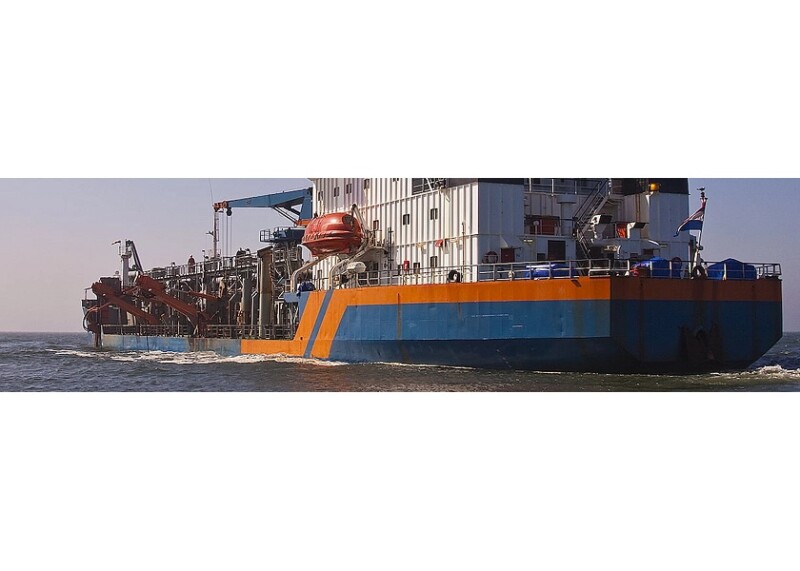

Althen Sensors & Controls BV (Netherlands) - A trailing suction hopper dredger is equipped with Althen propeller shaft earthing sets. The sets protect the propulsion machinery and prevent excessive maintenance costs.

A trailing suction hopper dredger is a vessel used to maintain navigable waterways, deepen silted channels or harbors, and remove or pile up sand on shores and beaches. For this purpose, the dredger has large, powerful pumps and engines that can suck up sand, clay, silt and gravel.The propeller shafts are equipped with Althen propeller shaft earthing sets. In order to ensure proper operation of the shaft earthing set, a potential monitoring set that visualizes the condition of the shaft earthing set has been installed as well.

Propeller shaft earthing:

Even on ships that are equipped with a sacrificial anode system, spark erosion may occur and damage the shaft bearings of the propulsion machinery. Ship owners can save a lot of money when they avoid such damage. The best way to do so, is to invest in a propeller shaft earthing set. The quality of this system is defined by the slipring and earthing brushes that must have a very low electrical resistance in order to direct the electrical current that flows through the propeller shaft to the hull of the ship.

Components propeller shaft earthing system:

In order to direct the electrical current that flows through the propeller shaft to the hull of the ship, a proper PSE system contains parts that have a very low electrical resistance. The main component of the Althen PSE system consists of is a copper slipring with a solid silver inlay that is supplied with two stainless steel clamping bands including dedicated connectors. Furthermore a brush holder is supplied which holds two silver/graphite brushes (80% Ag) that run over the silver track of the slipring. The brushholder is connected to the hull of the ship by means of an earthing cable. It has been proven that this set ensures optimal electrical continuity, which reduces total cost of ownership.

Potential monitoring:

In addition to the propeller shaft earthing set, a monitoring set has been installed. Potential monitoring is used for predictive maintenance as it visualizes the condition of the propeller shaft earthing set on an analog mV-meter. When the shaft earthing set is working properly, the mV-meter should indicate a value below 50mV. Exceeding the 50mV means malfunction of the PSE system, which may be related to filthy or worn parts, or incorrect installation.

Additionally the monitoring set can be supplied with a 4-20mA converter that offers an additional alarm function. This function can be used to send a signal to the bridge when the potential difference becomes too high due to malfunction of the PSE system.

For more information about the installation of the Propeller Shaft Earting System please download the user manual with instructions and technical drawings.

Please let us know what you measuring challenge is, and how we can help you.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.