ArtiMinds Robotics GmbH (Germany) - ZF Friedrichshafen relies on a special programming software environment for the simulation of robot applications, the generation of program code using a modular principle and the reduction of maintenance costs as well as to be able to work independently of manufacturers and to alleviate the lack of skilled workforce.

One of the world's largest automotive suppliers started 105 years ago as a gear factory (in German Zahnradfabrik “ZF”). Today, ZF Friedrichshafen has 230 locations in 41 countries and nearly 150,000 employees, generating sales of approximately 37 billion euros annually.

ZF Friedrichshafen uses numerous industrial robots for production, and, especially through acquisitions, new models from other manufacturers are constantly being added. This variety of robot systems alone is a challenge for ZF. In addition, the market for robots is developing rapidly. Where there used to be only the large industrial robots in the production lines, more lightweight robots have recently been added. They are also known as collaborative robots because they are designed to support employees directly at their workstations, without an enclosure. Their programming, however, still requires an expert.

Uwe Wachter is head of the Production Tech Center Robotics and Vision at ZF Friedrichshafen. He reports, "About three and a half years ago, we founded the Production Tech Center Robotics based in Schweinfurt. We are the division within the ZF Group that is responsible for new production technologies such as lightweight robots, camera systems or software solutions (including artificial intelligence). In principle, anyone in the ZF Group who needs support in these areas can come to us. We act as an internal service provider by support with advice, development and training."

In his role as a technology scout and consultant, Uwe Wachter is always looking for new solutions that make working at ZF easier. That is how he became aware of the ArtiMinds software and recalls, "After the first talks and presentations I knew: that's exactly what we need. The Robot Programming Suite enables us to do universal robot programming at a qualitatively higher level."

This is the highlight of the Robot Programming Suite (RPS): Developing a robot application in the RPS and letting it run on different robot systems at any time. Wachter explains, "If, for example, we develop an application for robots from manufacturer A in Schweinfurt, we can then generate the executable program for robots from manufacturer B from this source code and send this program by e-mail to our plant in Portugal. Then the colleagues in Portugal can run the same production with their robot system B as we do in Schweinfurt with robot system A. Only the software from ArtiMinds offers us this flexibility."

Since Wachter discovered the ArtiMinds Robot Programming Suite for himself and his team, he has been using it to develop solutions for a wide range of tasks. Three such robot applications will be briefly introduced:

- The use of a lightweight robot in a laboratory environment,

- the creation of simulations for feasibility studies and

- the development of an application for a task that was previously considered impossible to automate.

The robot as a flexible laboratory assistant

ZF Friedrichshafen operates a large laboratory at the Schweinfurt plant for various analyses, such as material testing. Wachter explains, "Up to now, a stationary system in a separate room was available for X-ray images. Because this installation is inflexible, the colleagues from the laboratory have additionally purchased a mobile X-ray unit."

This device can be thought of as a hand scanner. To produce a good X-ray image, the mobile X-ray unit must be guided along the workpiece at a constant speed and at a constant angle of attack. Combined with the protection against X-rays, in principle this task would be ideal for a lightweight robot.

The problem, however, is the variety of workpieces and the associated different requirements. Wachter's colleague Jonas Arnold, engineer for collaborative robots, explains, "Different parts have to be inspected every day. Today, 300 gears are to be tested. Tomorrow it will be a piston rod of batch size 1. The robot functions like a human arm, but can move along the different geometries much more precisely and flexibly. However, for each inspection, i.e. for each sequence of movements, the robot must be reprogrammed."

Until now, robot programming has been a task for experts. The laboratory staff lacked the necessary qualifications. How did ZF solve the problem? Wachter, "With the ArtiMinds Robot Programming Suite, we were able to provide our colleagues in the lab with predefined program modules. With the help of wizards, the lab technicians can easily configure the robot's motion sequences. This is done quickly and only basic knowledge is required."

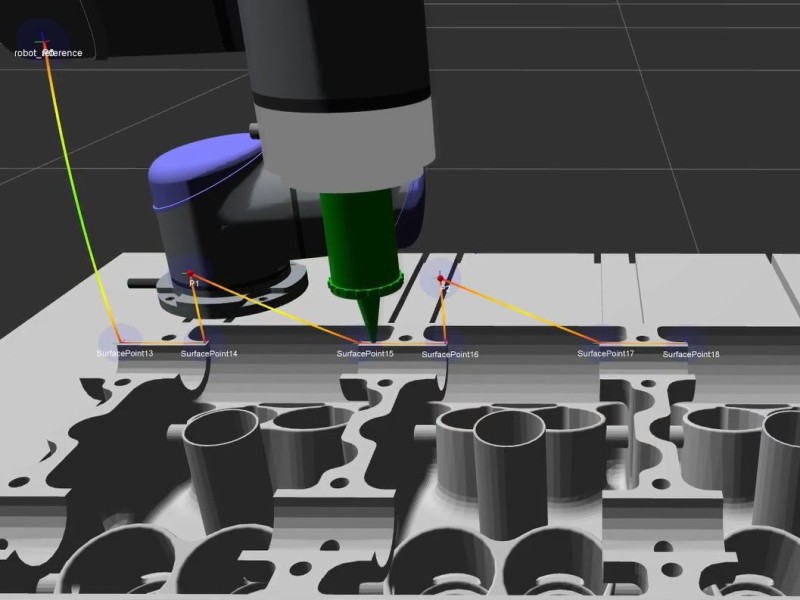

For simple geometries, a linear movement between two points is sufficient. For more complex tasks, the robot can orient itself on the CAD model of the respective test part. The CAD2Path feature, which creates a program based on CAD data loaded into the software, helps here.

Wachter summarizes. "The simplified configuration via the Robot Programming Suite was what made this type of application in the laboratory environment possible in the first place. Even non-experts can program robots and check the result in a visual simulation."

Simulate, then realize:

Simulations are one of the main tasks of the Production Tech Center Robotics anyway. For this purpose, Arnold regularly uses the Robot Programming Suite. He explains, "We are often confronted with the task of estimating whether or not a robot can meet a certain cycle time in a given situation. In simple cases, it is easy to estimate this. But in more complex projects we have to make a feasibility study.”

In the past when faced with the task of conducting such feasibility studies, ZF had to install the robot system on site at great expense, develop the appropriate application and test whether the system could meet the specified cycle time. With the Robot Programming Suite, ZF can not only program but also simulate applications, thus saving time and costs. Jonas Arnold explains, "The visualization allows us to identify potential problems in advance. This already starts with the spatial conditions. Does the available space even offer sufficient freedom of movement?"

In addition, when using collaborative robots, special standards must met in order to ensure the safety of human-robot collaboration. Arnold explains, "We must evaluate in advance, for example, where collisions between humans and robots could be possible. Can the robot arm reach head height? Are there possible clamping points? In order to ensure safety, we have to comply with force as well as pressure values and limit the speed of the robot's movements. During the gripping process, we must allow for inaccuracies that cause time delays. We can assess all of this more easily by simulating it with the Robot Programming Suite."

On the basis of such a technical feasibility study, ZF can then also estimate whether the use of robots is financially worthwhile for the respective task. Wachter comments, "In the end, it is always a question of whether we can meet a certain target. A lightweight robot, which is supposed to work with a cycle time of 20 to 30 seconds, the hardware, programming, and installation, must not exceed a defined price. With the help of a simulation, we can quickly and at an early stage assess whether we can meet this target."

Jonas Arnold concludes, "For me, the greatest advantage of the RPS is the many flexible features that allow us to simulate applications even before they are actually built and also to implement new, previously non-automated tasks.”

Open for special requirements:

Uwe Wachter and Jonas Arnold have already gathered several years of experience in a wide range of applications. And still, they too often encounter applications that are not so easy to implement. They find, "Airbags are sewn together in a ZF plant in Portugal. The challenge is to keep the sewing speed constant, even if the airbag does not have a uniform geometry." Realizing this task with a robot proved to be unexpectedly difficult. Because, according to Arnold, "The robot sits almost centrally from the component. This means that depending on how far and at what angle the robot arm has to move, the speed of movement would have to be adjusted continuously." The colleagues from Portugal had tried for several weeks to solve this task and finally gave up. Even with external system integrators, the requirements did not seem to be feasible.

Together with the ArtiMinds project team, ZF was finally able to work out a good solution for the implementation of the robot program. Arnold praises the cooperation and close collaboration, "We always come to ArtiMinds with special requests. There we always find open ears and helpfulness. In this way a beautiful and stable partnership has developed between us.”

Alleviate shortage of skilled workforce:

Wachter and Arnold are sure that the use of robots will continue to gain importance at ZF in the future. Because they see great potential especially in the automation of non-value-adding processes or areas that could not be automated up to now, but which represent a high physical strain or monotonous work. Wachter explains, "Staff qualified specifically for classic robot programming is rare. With the RPS, we can alleviate this shortage, at least selectively, by facilitating the implementation of robot applications with the help of the software." Furthermore, digital modern tools are much more popular with young junior staff than complex program code. "This also makes working at ZF more attractive."

The robot is maintaining itself:

ZF is currently evaluating the ArtiMinds Tool Learning & Analytics for Robots (LAR). Arnold already has a clear idea of how this feature can help him, "The effort required for the maintenance of robot systems is a big problem for us. We have some applications where wear and tear as well as changes in material properties over time change the entire system. LAR could help us to intervene at an early stage and make corrections with a few clicks or even allow the robot to adapt autonomously.”

In larger systems, re-teaching can take several days, during which time the system is at a standstill. This is exactly where Learning & Analytics for Robots comes in. During operation, LAR continuously collects data on every movement performed. On the basis of this data collection, the software can detect and warn at an early stage if, for example, inaccuracies occur in the gripping movement. Costly maintenance work is avoided.

Wachter concludes, "By using the ArtiMinds Robot Programming Suite we were able to reduce the costs for the development of robot applications. With Learning & Analytics for Robots, we will also be able to reduce maintenance costs in the future.”

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.