Total Cost of Ownership for Robots and AMRs

- October 29, 2025

Total Cost of Ownership for Robots and AMRs When calculating automation ROI, most teams underestimate long-term costs. Total Cost of Ownership (T...

Read MoreRobotic Welding for SMEs: Fixturing and Programming

- October 29, 2025

Robotic Welding for SMEs: Fixturing and Programming Small and medium manufacturers often see robotic welding as out of reach. Yet modern cobot we...

Read MoreErgonomics Wins: How Cobots Reduce Injuries and Absence

- October 29, 2025

Ergonomics Wins: How Cobots Reduce Injuries and Absence Repetitive strain and awkward postures cause thousands of lost workdays annually. Cobots...

Read More10 Real HRC Applications: Assembly, Screwdriving, and Testing

- October 29, 2025

10 Real HRC Applications: Assembly, Screwdriving, and Testing Human-Robot Collaboration (HRC) has matured from lab demos to real factory deployme...

Read MoreFrom Sim to Shop Floor: Commissioning Bin-Picking Cells

- October 29, 2025

From Sim to Shop Floor: Commissioning Bin-Picking Cells Simulation-to-production workflows have become essential in robotic bin-picking projects....

Read MoreCycle Time vs Accuracy: Tuning Trade-Offs

- October 29, 2025

Cycle Time vs Accuracy: Tuning Trade-Offs In 3D bin picking, faster isn’t always better. Every millisecond saved in cycle time risks reduce...

Read MorePath Planning for Random Bins: Practical Tips

- October 29, 2025

Path Planning for Random Bins: Practical Tips Path planning determines how a robot moves from vision detection to successful grasp. In random bin...

Read MoreForce-Torque Sensing for Delicate Handling

- October 29, 2025

Force-Torque Sensing for Delicate Handling When robots handle fragile or tight-tolerance parts, vision alone isn’t enough. Force-torque sen...

Read More3D Bin Picking That Works: Vision, Motion, and Grippers

- October 29, 2025

3D Bin Picking That Works: Vision, Motion, and Grippers 3D bin picking promises to eliminate manual sorting and feeding, but in practice, many sy...

Read MoreScaling from 1 to 10 Sites: Lessons Learned

- October 29, 2025

Scaling from 1 to 10 Sites: Lessons Learned Launching one micro-fulfillment center is hard; scaling ten is an entirely different challenge. Consi...

Read MoreRobotic Picking Accuracy: Vision, Grippers, and Feedback

- October 29, 2025

Robotic Picking Accuracy: Vision, Grippers, and Feedback Picking accuracy defines the success of warehouse robotics. As item diversity grows, rob...

Read MoreG2P vs G2G: Choosing Your Robotic Picking Strategy

- October 29, 2025

G2P vs G2G: Choosing Your Robotic Picking Strategy Two main paradigms dominate warehouse automation: Goods-to-Person (G2P) and Goods-to-Goods (G2...

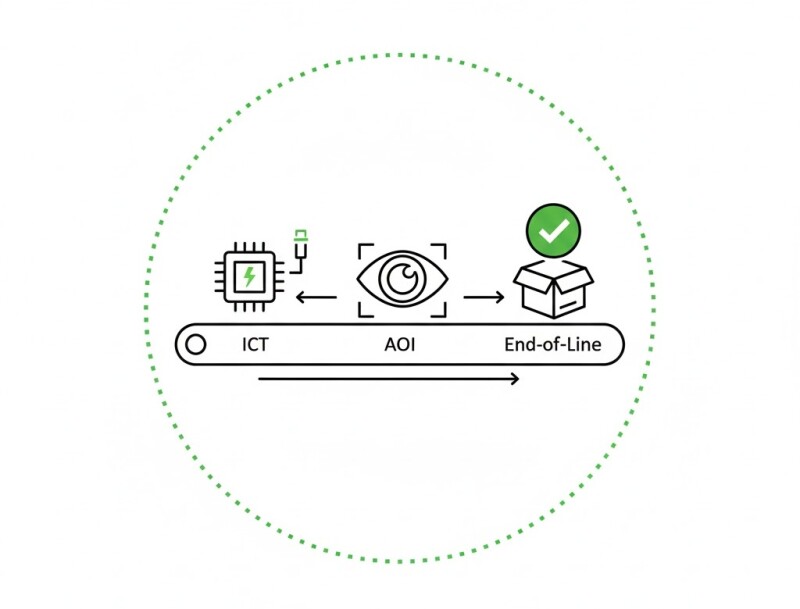

Read MoreIn-Line Test Automation: ICT, AOI, and End-of-Line

- October 28, 2025

In-Line Test Automation: ICT, AOI, and End-of-Line Testing is the final gate before shipment — and the most data-rich step in electronics m...

Read MoreHow EMS Providers Automate Without Killing Flexibility

- October 28, 2025

How EMS Providers Automate Without Killing Flexibility Electronic Manufacturing Services (EMS) companies thrive on high product variability. But...

Read MoreRobots for Tiny Tolerances: Vision and Force Strategies

- October 28, 2025

Robots for Tiny Tolerances: Vision and Force Strategies Electronic assemblies often demand sub-100-micron accuracy. Achieving this repeatably req...

Read MoreHigh-Mix Robotics: Soldering, Dispensing, and Micro-Assembly

- October 28, 2025

High-Mix Robotics: Soldering, Dispensing, and Micro-Assembly In electronics manufacturing, high-mix, low-volume production has always challenged...

Read MoreESD-Safe Automation: What Integrators Forget

- October 28, 2025

ESD-Safe Automation: What Integrators Forget Electrostatic discharge (ESD) can silently destroy microelectronic components. As robots take over h...

Read MoreDIY Robotics Cells: Safe, Simple, and Repeatable

- October 28, 2025

DIY Robotics Cells: Safe, Simple, and Repeatable Do-it-yourself robotics has evolved from hobby projects to legitimate industrial solutions. SMEs...

Read MoreCollaborative vs Industrial Robot Safety: What Changes

- October 28, 2025

Collaborative vs Industrial Robot Safety: What Changes Collaborative robots (cobots) and traditional industrial robots follow the same core safet...

Read MoreFunctional Safety for Robotics: PL, SIL, and Safe Motion

- October 28, 2025

Functional Safety for Robotics: PL, SIL, and Safe Motion Modern robots depend on electronics for safe operation. Functional safety ensures that h...

Read More