Open PLCs and Linux-Based Controllers: Pros and Cons

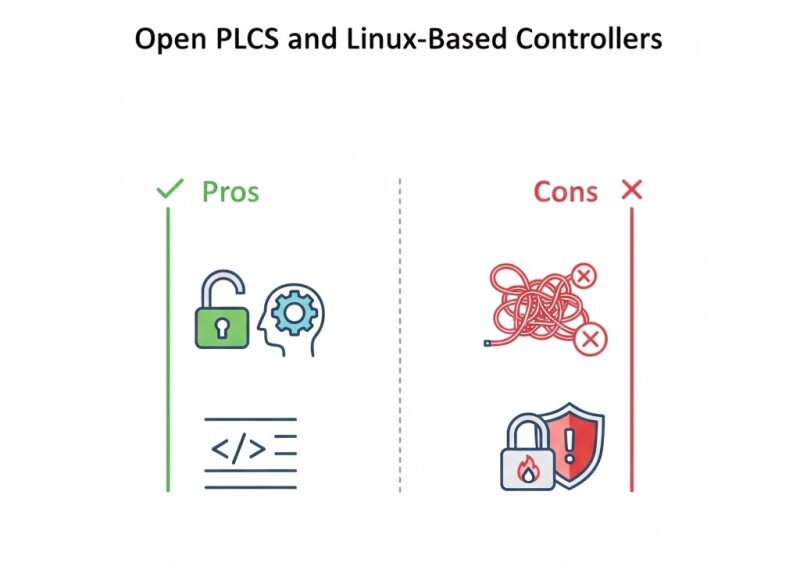

Industrial control is evolving beyond proprietary rack PLCs. A new wave of open, Linux-based controllers — like PLCnext, Codesys Control, and OpenPLC — brings flexibility, openness, and edge-AI integration to automation engineers. But openness comes with trade-offs.

The Promise of Open PLCs

- Freedom of architecture: Run IEC 61131-3 code alongside Python or C++.

- Integration power: Easy connection to MQTT, REST, and OPC UA stacks.

- Hardware choice: Works on x86, ARM, and industrial PC platforms.

The Risks

- Hard-real-time limits: Linux scheduling adds micro-latency vs dedicated PLCs.

- Security footprint: Open OS requires patching, firewalls, and user control.

- Qualification effort: Regulatory approval may take longer in GMP or automotive environments.

Best-Fit Scenarios

- Hybrid systems where AI inference or data logging runs next to control logic.

- Retrofits where replacing I/O hardware isn’t viable.

- Applications needing web-based dashboards or APIs directly on the controller.

Case Example

A machine builder adopted a Codesys Linux runtime on IPC hardware. Integration with Python libraries for predictive maintenance saved two separate devices and cut latency by 40 ms.

Related Articles

- From Ladder to Structured Text: When (and How) to Switch

- Version Control for PLC Projects: Git without the Pain

- Lifecycle and Spares: Designing for 5-Year Support

Conclusion

Open PLCs aren’t for every factory, but they’re shaping the next decade of control. When combined with proper security and deterministic design, Linux-based control can deliver both flexibility and reliability.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.