Minebea Intec (Germany) - Press Release: Minebea Intec, a leading global provider of industrial weighing and inspection solutions, proudly celebrates the 75th anniversary of its Aachen site on 26 November. Not only is the inspection business managed from here, but checkweighers and metal detectors are also manufactured and software is developed in the Aachen production halls.

The portfolio also includes X-ray and visual inspection systems as well as automatic price labelling systems. These technologies ensure maximum product quality and efficiency in the food, pharmaceutical and cosmetics industries. Minebea Intec can look back on a long history at the Aachen site, characterised by pioneering developments and continuous progress.

The history of Minebea Intec's Aachen site began in 1948 with the company Dr Hans Boekels GmbH & Co, which developed metal detectors for detecting unexploded ordnance and bombs. In the following decades, the development of metal detection technology was driven forward, primarily by increasing automation in the food industry and the associated risk of contamination. The introduction of phase rectifiers at the end of the 1970s enabled better suppression of interfering product signals. Adaptation to ever higher frequencies increased detection sensitivity. Today, Minebea Intec metal detectors operate at frequencies of up to 1 MHz. This enables a maximum search sensitivity of 0.2 mm with the smallest coil and highest frequency - which means that the company can confidently count itself among the most advanced manufacturers in the industry.

In addition to metal detection technology, Dr. Hans Boekels GmbH & Co. revolutionised the dynamic checkweigher in 1969 with EMFC load cells developed in-house. In 1998, Sartorius AG took over the Boekels company. Ten years later, the product range was expanded to include X-ray inspection systems. Following the takeover by the MinebeaMitsumi Group, the company was renamed Minebea Intec in 2016.

Innovation at Minebea Intec: X-ray inspection system Dypipe and metal detector Mitus®:

Innovation is the key to Minebea Intec's success. "We pride ourselves on constantly setting new standards for the industry," says André Stoppelenburg, Head of the Inspection Division at Minebea Intec. "One example of our innovative strength is our new Mitus® metal detector with flexible MiWave technology, which enables high-precision detection of metallic foreign objects." With this new technology, products can be symbolically inspected from multiple perspectives. This ensures a significantly higher information content and therefore an even higher search sensitivity. The result for manufacturers: maximum product safety and maximum output.

The Dypipe X-ray inspection system is also one of the innovations that Minebea Intec launched onto the market just this year. X-ray inspection systems are used in industry when producers want to reliably detect and eject foreign bodies such as stone, plastic particles, bone and glass as well as metal, or check fill levels. "Our Dypipe X-ray inspection system offers unrivalled flexibility for the inspection of viscous and liquid products," says André Stoppelenburg. "With various separators, connections and mounting options, customers can optimise their production lines." An innovative test part insertion system enables the validation of test parts during operation and specially developed reject valves ensure maximum hygiene, especially in meat applications.

Products, advice and service from a single source:

Minebea Intec offers a broad portfolio of weighing and inspection technologies. In addition to these products, customers also receive checkweighers, industrial scales, load cells, visual inspection devices and automatic price labelling systems. The company also offers comprehensive consulting and services. Minebea Intec's customers therefore not only benefit from the company's many years of experience, but also have a competent partner at their side throughout the entire project planning process thanks to this holistic approach.

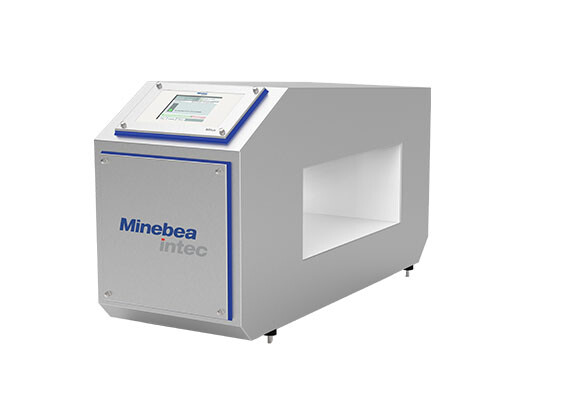

Image 1 Caption:

Minebea Intec's inspection technologies ensure the highest product quality and efficiency in the food, pharmaceutical and cosmetics industries, among others.

Image 2 Caption:

Minebea Intec employs 163 people at its Aachen site.

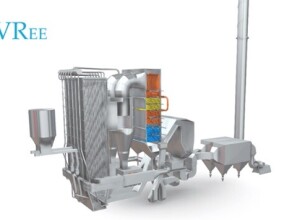

Image 3 Caption:

Thanks to innovative MiWave technology, the Mitus® metal detector detects even the smallest metallic foreign objects, even with the largest product effect.

Image 4 Caption:

The Dypipe X-ray inspection system ensures an extremely high level of safety for vis-cous and liquid products.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.