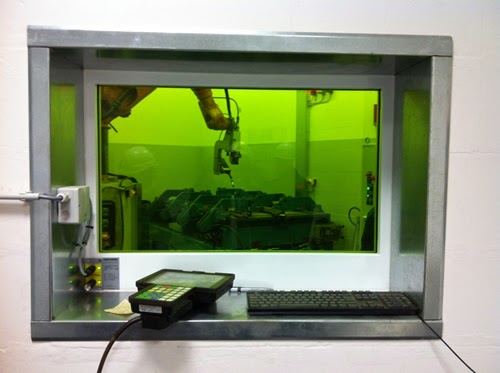

Pilz GmbH & Co. KG (Germany) - MEYER WERFT in Papenburg has equipped its laser welding laboratory for high-performance laser welding technology with a safety solution comprising the automation system PSS 4000, safe sensor technology PSEN and control and signal devices from Pilz. In conjunction with the safety gate system PSENsgate and the operating mode selector switch PITmode, PSS 4000 controls and monitors all the safety functions in the laser welding laboratory, meeting the highest safety requirements up to Performance Level e and Safety Integrity Level 3.

As well as taking care of basic passive safety, the control system PSSuniversal PLC from the automation system PSS 4000 also monitors all the safety-related signals on switches, the laser, robot and laboratory window. The safety gate system PSENsgate and operating mode selector switch PITmode, which enables the plant to be operated and controlled by authorised personnel in various operating modes, also monitor the access area of the laser welding laboratory.

"The holistic, flexible safety solution from Pilz can enable all current and future laser applications", says Frank Boekhoff, Head of the Joining Technology Division in MEYER WERFT's Research & Development department.

This website uses cookies. By browsing our website you accept the use of cookies. For more information read our Terms of Use.

MEYER WERFT uses safety solution from Pilz

- By Pilz

- Posted on Jan 25, 2015

For more information about this article from Pilz click here.

Interesting Links:

GameMarket.pt - Your Gaming Marketplace with Video Games, Consoles, PC Gaming, Retro Gaming, Accessories, etc. !

Are you interested on the Weighing Industry? Visit Weighing Review the First and Leading Global Resource for the Weighing Industry where you can find news, case studies, suppliers, marketplace, etc!

Are you interested to include your Link here, visible on all AutomationInside.com articles and marketplace product pages? Contact us

GameMarket.pt - Your Gaming Marketplace with Video Games, Consoles, PC Gaming, Retro Gaming, Accessories, etc. !

Are you interested on the Weighing Industry? Visit Weighing Review the First and Leading Global Resource for the Weighing Industry where you can find news, case studies, suppliers, marketplace, etc!

Are you interested to include your Link here, visible on all AutomationInside.com articles and marketplace product pages? Contact us

© Pilz / Automation Inside

Previous article

Magnetic Sensor MSA111C from SIKO now also "speaks" DRIVE-CliQ!

Next article

Gesture and multi-touch operation of machinery and plant – on a 15" display from Siemens

Popular News

Automation Inside Newsletter

Popular Tags

Login

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.