Mercedes-Benz (Germany) - Press Release: Mercedes-Benz accelerates the transformation of its production network through the use of AI and humanoid robots at its Digital Factory Campus in Berlin.

Mercedes-Benz is speeding up the transformation of its production network by strengthening the status of Berlin-Marienfelde as an innovation hub for MO360 digital production technologies, now enhanced with Artificial Intelligence (AI), humanoid robots, and pioneering innovations such as the production of high-performance axial flux electric motors.

In 2022, Berlin-Marienfelde established itself as the global competence center for production digitalization with the Mercedes-Benz Digital Factory Campus (MBDFC), fostering the development of future software applications in a real production environment. The central foundation of these activities is the Mercedes-Benz Cars Operations 360 digital production ecosystem (MO360), which integrates all key software applications and data from the global production network. At MBDFC, the development and testing of new processes and technologies have been combined with the seamless global implementation of pioneering MO360 software applications for automotive production.

Mercedes-Benz has now refined its MO360 production system with AI capabilities, such as the Digital Factory Chatbot Ecosystem and the MO360LLM Suite, alongside humanoid robots from U.S.-based company Apptronik, reinforcing Berlin-Marienfelde as a global innovation center. Today, new production processes and features, including those enabled through the Mercedes-Benz Operating System (MB.OS), are tested before being deployed to real assembly lines in other Mercedes-Benz plants. Marienfelde, for instance, played a key role in preparing the Rastatt plant for ramping up production of the new Mercedes-Benz CLA, the first vehicle to incorporate MB.OS, which was unveiled just days ago.

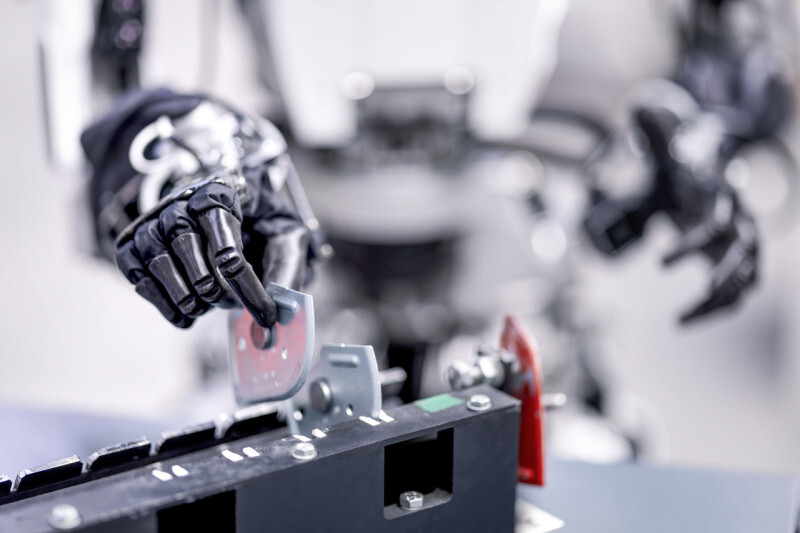

Berlin-Marienfelde: A Testing Ground for Highly Automated Robotics in Production

Mercedes-Benz is committed to empowering its workforce with cutting-edge technology – and with Apollo, the brand is introducing one of the most advanced commercial humanoid robots to its manufacturing facilities. To emphasize its commitment to deploying humanoid robots in automotive production, Mercedes-Benz will invest a low double-digit million-euro amount in Apptronik, which was founded in 2016 at the Human Centered Robotics Lab at the University of Texas at Austin.

Since the 1970s, Mercedes-Benz has used industrial robotics technology for particularly monotonous and physically demanding tasks. Today, the company is testing the integration of humanoid robots in production, initially focusing on repetitive tasks within intralogistics. Apptronik’s Apollo can be used to transport components or modules to the production line, where highly skilled Mercedes-Benz employees assemble them, and to perform initial quality checks on components.

The Apollo robots have been collecting data in a production environment to train for specific use cases within MO360. Mercedes-Benz employees, with real production expertise, have transferred their knowledge to Apollo using teleoperation and augmented reality processes. Now, Mercedes-Benz is taking the next decisive development step at the Digital Factory Campus in Berlin – enabling Apollo robots to perform autonomous operations, a technological milestone on the path toward a flexible and intelligent assistance system for production.

In December, the AI-powered humanoid robotics company Apptronik announced a strategic partnership agreement with Google DeepMind’s robotics team to merge cutting-edge AI with advanced hardware, advancing humanoid robots to be more useful to people in dynamic environments.

Artificial Intelligence for All: Smart Assistants in Daily Production

Artificial Intelligence is transforming the world, and at MBDFC, Mercedes-Benz is proactively shaping and creating new smart technologies for use in its global production network. Thanks to the MO360 AI Factory, AI is being brought directly into production in an intuitive, accessible, and user-friendly way. The in-house development of the Digital Factory Chatbot Ecosystem allows employees to access production databases: Questions about machine maintenance or best practice methods for manufacturing processes can be asked via chat, and AI instantly provides accurate answers in multiple languages.

Another example of AI-driven efficiency is the virtual multi-agent system. AI-powered virtual assistants analyze complex data in real time and can, for example, quickly identify the root causes of sudden quality deviations in production. Instead of manual, time-consuming root cause analysis, engineers rely on AI agents from a virtual data science team. These AI agents swiftly and reliably analyze available data, identify patterns and anomalies, and provide well-founded insights and solution suggestions at the push of a button, delivering real efficiency gains in production.

Transforming Marienfelde with Axial Flux Technology

In addition to developing new production processes, the Marienfelde site has for decades been an important part of Mercedes-Benz’s global drivetrain production network, manufacturing various powertrain technologies. As the global automotive industry transitions from combustion engine technologies to an all-electric future, Mercedes-Benz is establishing Berlin as a center of excellence for high-performance electric motor manufacturing.

Starting next year, the cutting-edge axial flux motor will roll off the Marienfelde production line. The manufacturing of an axial flux motor involves about 100 production processes, of which 65 are entirely new to Mercedes-Benz, and 35 are completely new to the world. New ways of applying laser technologies have been combined with adhesive bonding processes and AI, to name just one example.

These new production techniques were primarily developed in-house, and the innovations have resulted in over 30 patent applications – all highlighting Marienfelde’s global pioneering role in production process innovations.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.