VIA Technologies, Inc. (Taiwan) - Once pure science fiction, now rapidly science fact, the use of autonomous robots in warehousing applications is one of the major trends for 2019 and beyond.

IDC predicts that worldwide spending on robotics systems and drones will total $115.7 billion in 2019, an increase of 17.6 per cent over 2018, a trend set to continue out to 2022, when spend will reach $210.3 billion.

According to IDC analyst John Santagate, 60 per cent of the world’s 2,000 largest companies will have deployed autonomous mobile robots by 2021, and the relentless logistical challenges of fulfillment have made the sector a particularly early adopter.

Take Aim at Omnichannel:

Familiar market drivers such as cost efficiency and staff management may be part of the story. But excitingly the underlying requirement is immediacy. As pioneered by Amazon – which has more than 100,000 robots operating at over 26 order-fulfillment centers worldwide – the key for retailers and enterprise suppliers alike is next-day delivery and omnichannel fulfillment, increasingly driven behind the scenes by AI and Edge AI robotics.

It’s a busy market. In November 2018, logistics firm DHL announced a $300 million modernisation programme to install robots and IoT sensors across 60 per cent of its warehouses in North America in order to keep pace with demand. While China’s Alibaba is said to already use robots to carry out 70 percent of tasks.

Anticipatory shipping isn’t a new idea, but as expected shipping times shrink for businesses and consumers alike, the ability to pre-ship stock to distributed depots for almost immediate delivery, rather than in regional hubs, has become a crucial battleground. Here sophisticated AI fulfillment strategies are predicting (and learning) what items, brands and volumes will be required day by day, postcode by postcode.

The benefits in customer loyalty and repeat spend are significant in this same-day delivery model, which coupled with the 24-hour operation enabled by warehouse robots and the savings on warehouse heating and lighting (which robots mainly do not require), makes the market acceleration entirely understandable.

On-device Intelligence Increases Precision:

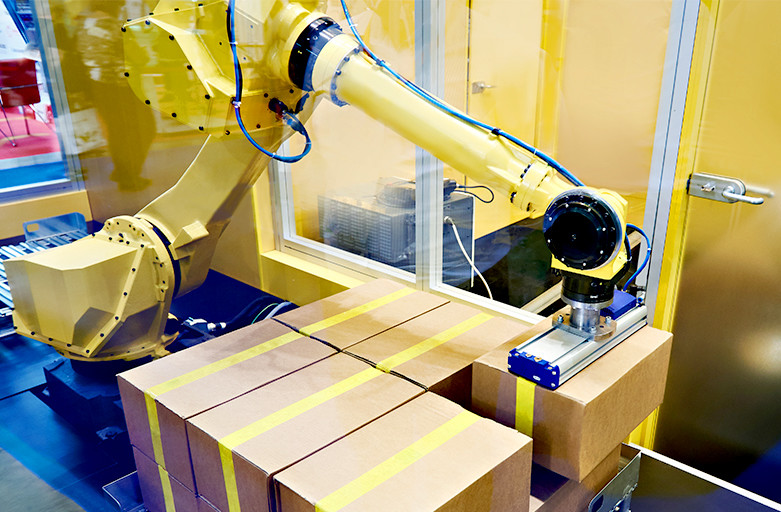

Even given perfectly tuned smarter AI-powered fulfillment backends that can orchestrate the bigger picture, picking and packing has to be more science than art, which is where robots really shine. In all but a few examples (bags of oranges being one), automated picking and packing saves time and money, as well as being highly predictable, an essential element in an AI-powered fulfillment chain.

Increasingly potent on-device processing means faster, more mobile machines that are less reliant on the local network bandwidth for second-by-second guidance, while vastly improved depth-sensing technologies have enabled packing speed and accuracy to reach industry leading levels – for example, Ocado’s robotic warehouse in the UK can pick a typical 50 item shop in just five minutes.

The trend driving depth sensing innovation is a move away from cumbersome and expensive laser technology towards depth-sensing camera technologies, which carry far lower unit costs, and are less physically cumbersome and more easily adapted to co-working environments. For example, the forthcoming VIA Edge AI 3D Developer Kit’s AI depth solution features the tiny VIA SOM-9X20 Module and Lucid’s proprietary 3D Fusion Technology, a combination that tackles the fast scaling required by depth sensing, provides native multi-camera support as well as reducing power, costs and space overheads.

Healthy Developer Community:

It is no wonder that the developer community for this robotics sector is booming, with dedicated developer kits such as the VIA Edge AI Developer Kit providing a single package of core hardware and software components that dramatically cut the cost and complexity of designing, testing, and deploying next-generation Edge AI systems and devices.

Affordable and accessible developer kits not only lower the barriers to entry for existing enterprises to develop robotic warehousing prototypes, but also encourage young innovators to apply new methods to existing problems. This mindset is being nurtured by a range of competitions and challenges in this space, such as Amazon’s annual ‘picking challenge’, and the Robotics Best Paper Awards in Manipulation.

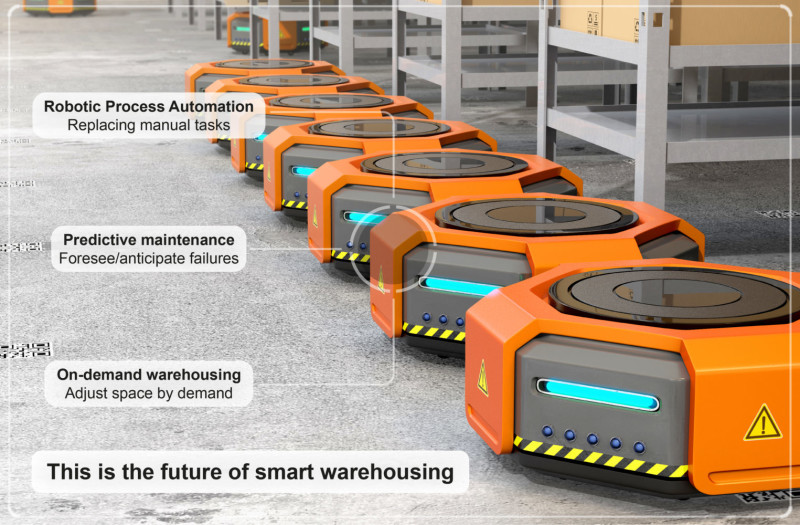

Future is On-demand:

While the market for Edge AI-powered warehouse robots will continue to evolve, the enabling technologies will begin to deliver a vast range of new enterprise opportunities too. One example is warehousing on demand, where owners of space can lease it on a flexible basis, as and when it is needed, opening up that final mile to all businesses, not just those with vast, Amazon-like fulfillment networks. Startups in the US and UK are already offering such on-demand services, which rely heavily on real-time visibility and highly accurate, rapid picking and packing that are the hallmark of Edge AI-powered warehouse robots.

The VIA Edge AI Developer Kit provides a tightly-integrated package for all device makers looking to kickstart the development of depth sensing capabilities in applications such as Edge AI warehousing. It is certain that this space will continue to grow exponentially, as fulfillment immediacy demand increases, and the value of increased productivity and 24-hour operation become more widely acknowledged. Welcome to the future of fulfillment!

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.