FormPak, Inc. (United States) - Manufacturers who use dry bulk solids in the production process incur a significant risk of liability involving workplace accidents or charges of unsafe working conditions.

Materials that come in powder form require stringent dust control measures to reduce that risk. Many dusts generate a static charge during bulk bag filling and discharge applications. This may lead to a dust explosion if the problem is left unaddressed.

Plant managers must also take steps to prevent unwanted employee exposure to inhalable particulates. Employers may be exposed to exhorbitant fines and costly litigation over charges of negative health effects stemming from workplace dust exposure.

For example, several employees at one popcorn manufacturing plant were diagnosed with cancer that was determined to be linked to the powdered flavoring diacetyl. Although it is completely safe to eat, diacetyl is considered unsafe when inhaled. The National Institute for Occupational Safety and Health (NIOSH) has found multiple examples of employees in other popcorn plants developing health problems related to prolonged exposure to diacetyl dust.

To address the problem of dust inhalation, manufacturers must comply with regulations promulgated by the Occupational Safety and Health Administration (OSHA) and state entities like the California Air Resources Board (CARB). Choosing the correct bulk bag filling and discharging equipment is also critical to minimizing potentially harmful dust exposures and reducing the risk of costly enforcement actions.

OSHA PELs and General Duty Clause:

OSHA has established “permissible exposure levels” or PELs, which are legal limits for exposure to certain substances in the workplace. However, there are a number of substances for which OSHA has not established PELs. In these instances, it relies on recommended limits published by industry organizations such as the American Conference of Governmental Industrial Hygienists (ACGIH).

Exceeding PELs or industry-recommended limits may lead to charges of violating the General Duty Clause of the OSH Act. This provision requires employers to provide a workplace “free from recognized hazards that are causing or are likely to cause death or serious physical harm.” Manufacturers must also ensure that safety data sheets include all known exposure limits including those published by ACGIH where applicable.

California Air Resources Board:

Manufacturers must also comply with applicable state and local regulations in jurisdictions where production operations take place.

The Californial Air Resources Board (CARB) has primary resposibility to regulate air pollution and has established stringent permitting requirements for a range of industries. While many of its programs seek to reduce emissions of particulate matter from motor vehicles, CARB also regulates industrial plants, including indoor work areas. That includes efforts to limit employee exposure to potentially harmful inhalable particulates.

Examples of Inhalable Particulate Matter:

Airborne particulate matter is actually a mixture of solids and aerosols and may contain both organic and inorganic material. Particulates may be generated by burning fuels such as gasoline, oil, diesel or wood. Other sources include dust from construction sites, landfills, agriculture or industrial processes used in manufacturing various products.

When particles become deposited in the lungs, they may cause tissue damage and inflammation which sometimes leads to negative health outcomes. Short-term exposure to particulate matter has been associated with hospital admissions for people with heart or lung conditions, cases of acute or chronic bronchitis and asthma attacks. Those most at risk include children, older adults and individuals with pre-existing heart or lung conditions. Long-term exposure may increase the risk of premature death.

Powdered Flavorings:

Although OSHA hasn’t established PELs for powdered flavorings, it does point out that just because a substance is safe to eat doesn’t mean it’s safe to inhale. Furthermore, the presence of an inhalation hazard in the workplace may constitute a violation of the General Duty Clause of the OSH Act. Diacetyl is one such substance commonly used to flavor packaged foods. Health effects among exposed employees have included bronchitis and fixed airways obstruction.

Powdered Metals and Minerals:

Silicosis is a potentially fatal disease caused by exposure to silica dust in the lungs. Silica dust is often found in cement and masonry, which puts construction workers at risk of unwanted exposures. Inhalation leads to the formation of scar tissue in the lungs. Over time, nodules may form, which can interfere with breathing.

Carbon black is a super fine powder used in tires and other rubber products. It may also be used to add color to products ranging from inks to leather goods. It is also used in insulation for electrical equipment. Carbon black is a by-product of burning fuels, and carbon black particles often become coated with other chemicals that make them even more hazardous when inhaled. Short-term exposure may cause lung irritation. Long-term, it may cause chronic bronchitis, COPD and lung disease.

Raney nickel, also called nickel powder, is a finely powdered metal used in processing vegetable and petroleum oils. It is considered a carcinogen and may have adverse health effects when inhaled or absorbed through the skin. Short-term inhalation may irritate the nose, throat and lungs. While OSHA has established a PEL of 1 milligram per cubic meter over an 8-hour work shift, health experts recommend keeping exposure as low as possible.

Minimizing Dust Exposure during Bulk Bag Handling:

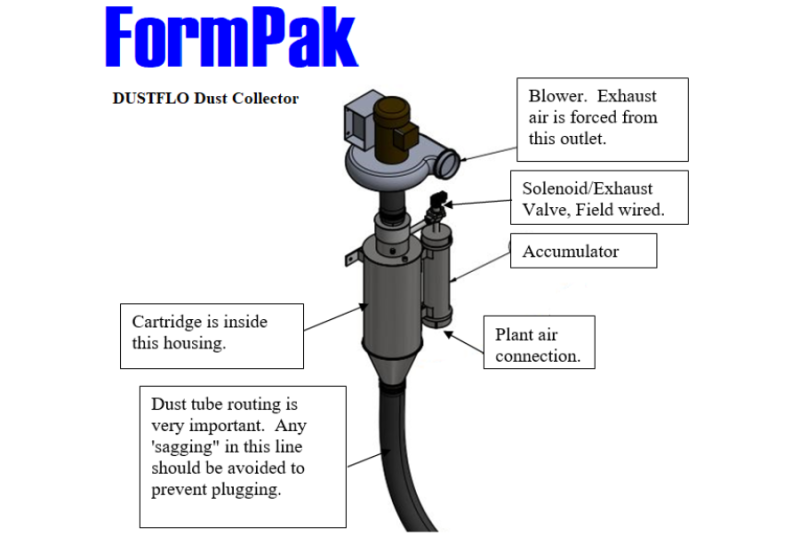

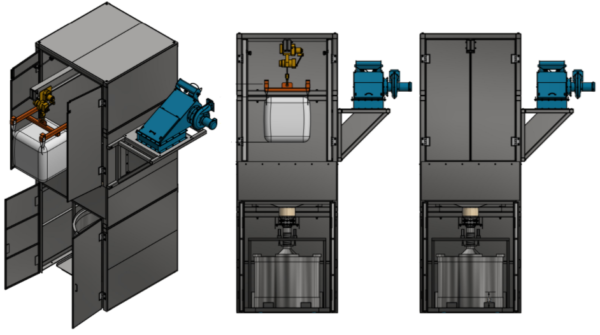

Workplace controls must include proper handling and storage of powdered materials to reduce the risk of inhalation and explosion. Flexible intermediate bulk containers, or FIBCs, must be tightly sealed during filling, storage, transport and emptying. Bulk bag fillers, unloaders and dumping stations, for example, must be designed for dust-free operations.

Equipment design must include dust-tight connections during filling and unloading. Optional features that enhance dust control include access doors and glove box access.

At FormPak, we offer a range of quality handling equipment to maximize safety and efficiency. We enable you to achieve dust-free handling of FIBCs that protects your company and your employees.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.