Airpes Sistemas Integrales de Manutencion Y Pesaje S.L. (Spain) - Press Release: Airpes has led the collaborative design of a new lifting tong for handling steel or aluminum coils ready for work in semi-automated and fully-automated electric overhead traveling (EOT) crane applications. Discover its features next.

New automation-ready lifting tong for steel:

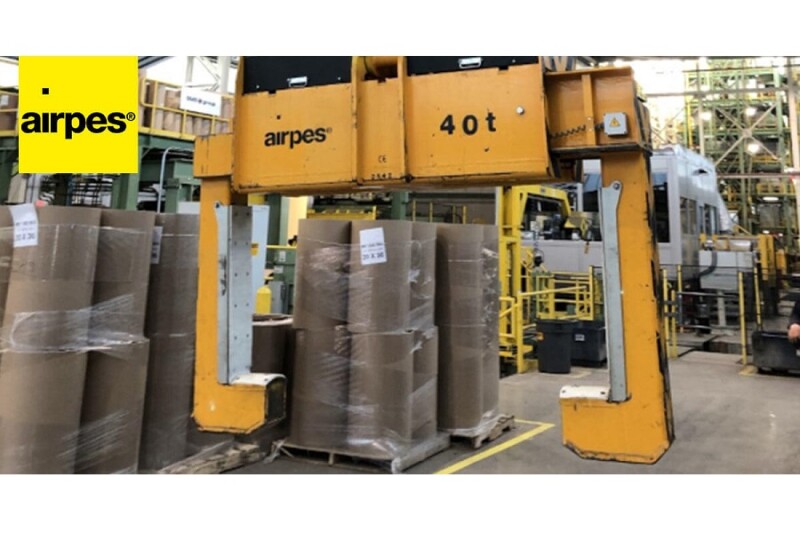

The percentage of new crane installations that require automation is growing, but it’s also growing the demand for retrofits and the requests for cranes to be able to be easily converted for more automation in the future. The new Airpes’ automation-ready lifting tong is designed to be a standard product that meets most of the needs of any automated crane with easily serviceable components.

Airpes’ automation-ready coil lifting tongs are typically used to lift 25 to 60-ton coils but can be adapted to suit end users’ requirements. They are compatible with any crane in the steel and aluminum sectors and can be installed as a retrofit or part of a new build.

The tong’s system meets Crane Manufacturers Association of America (CMAA) duty classification D, E, or F. CMAA Class F, for example, covers continuous severe service cranes, capable of handling loads approaching a rated capacity throughout their life.

Semi-automatic and fully-automatic applications:

Airpes’ new lifting tong is ready for work in semi-automated and fully-automated EOT crane applications. In semi-automatic applications, some of the lifting tong features assist the operator but allow more manual control. Using it in a fully-automatic mode can be useful in demanding environments, repeating the lifting process without manual input.

High precision and adaptable lifting tong:

Airpes’ automation-ready coil lifting tongs act in concert to position the crane within millimeters of the load, engage the tong to the load and carry it to a destination based on the work to be performed on the coil, the type of steel, and the size.

The automation-ready lifting tong can be adapted to a rigid mast crane, a wire rope hoist, an existing crane, in various capacities and duty cycles, but users get the same package of components that ensure repeatability and serviceability. A specific hook and lower block package can be retrofitted to the existing crane or built new. This contributes to the stability, the accuracy of positioning, and the anti-sway design.

A versatile lifting equipment:

The automation-ready coil lifting tong can land a coil not just in a fixed point like a storage rack or a de-coiler, but also on a truck or railcar. That’s a big deal because trucks and railcars have different configurations, wheelbases, deck heights, and are positioned differently every time. The tong can account for that and still land the coil perfectly. The computer always knows the most optimal path.

Enhance safety with our new automation-ready lifting tong:

Safety is enhanced because the automation-ready lifting tong process and ships a coil without touching it. By eliminating hand contact with coils, you can reduce injuries to hands and fingers that cost millions.

A collaborative project:

After years where the crane builder has to agree with the automation integrator with a custom package for the end-user in a time-consuming and less repeatable process with a lot of designs and rework, Airpes has collaborated now with partners as Janus Automation to serve this new automation-ready lifting tong.

Previously, there was no steel coil tong formally designed for automation applications, most were modified after delivery by the next person in the value chain. Designing for automation and involving engineers from various stakeholders, Airpes and its partners came up with something that presents a product that easily meets expectations and cuts down significantly on re-engineering and modification by the integrators and crane builders.

Airpes is your partner in automation-ready lifting equipment:

Airpes design, manufacture and install lifting and handling equipment around the world. We can provide you with on-demand solutions. Would you like to have an automation-ready lifting tong?

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.