Nitta Industries Europe GmbH (Belgium) - The seamless, highly flexible flat belts of Nitta’s Zeroseam line improve operating life and performance in the production of cardboard tubes for food packaging.

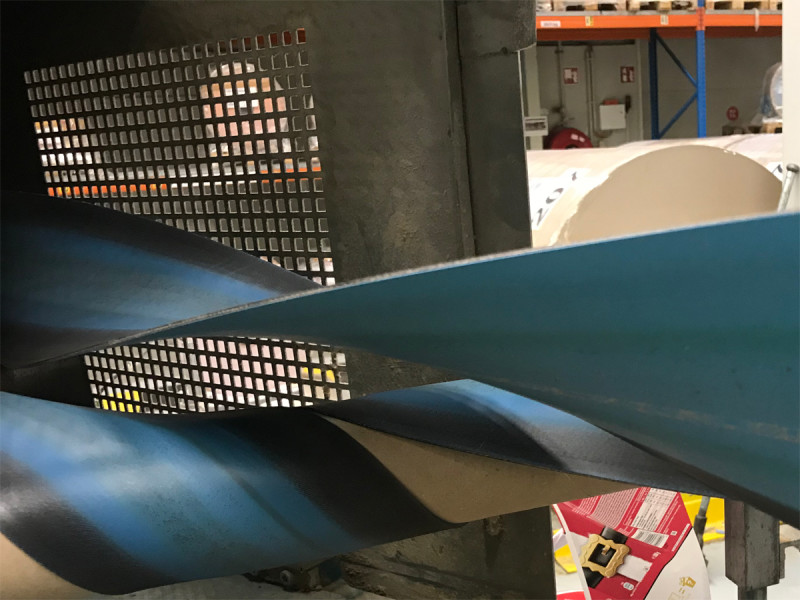

At Sonoco Consumer Products in Mechelen, Belgium, machines are hardly ever standing still, producing cardboard tubes for the food industry non-stop. Employing 20,000 people in 33 countries, the Belgian company is part of the Sonoco Group, a manufacturer of paper tubes and cores and supplier of a multitude of packaging solutions. As production time is of the essence, every minute saved in machine maintenance counts. A key factor in the frictionless performance of the spiral tube winding machines used for producing paper cores is the tube winding belt. This belt applies pressure to the product to achieve the required level of adhesion between the individual layers of paper. Requiring strong tension, high flexibility and a firm grip as well as abrasion resistance, this application poses a unique set of challenges for the belts’ design.

Due to the winding machines’ high production speeds, high levels of stress are exerted on the tube winding belts. The polyamide belts previously used at the Mechelen plant had to be replaced frequently, incurring significant maintenance costs and machine downtimes. Sonoco contacted Bogaert Transmission – Nitta’s partner in Belgium that has more than 35 years of experience in transmission and conveying solutions. Working together, Nitta and Bogaert’s service teams identified the rigidity of the belt material as the reason for the high wear. To increase the belts’ service life, they recommended Nitta’s new Zeroseam ZS-TWL-42H.

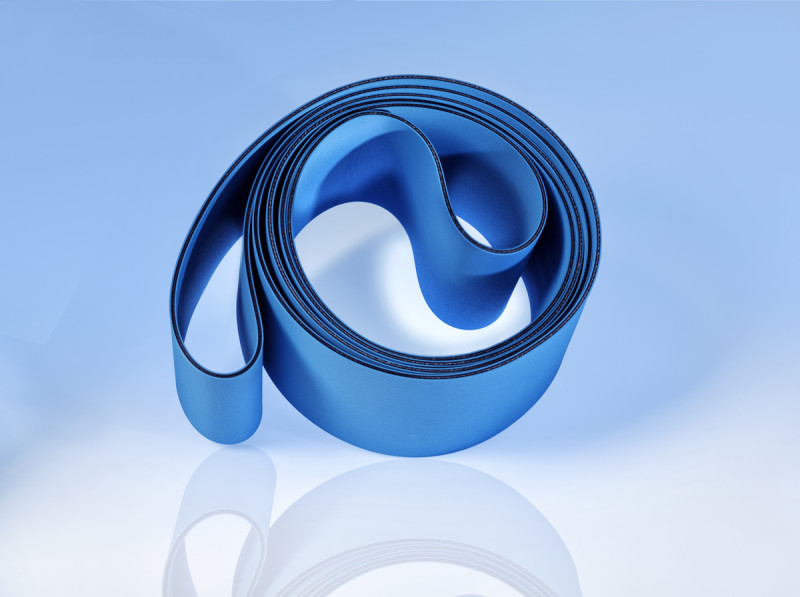

Featuring a strong, seamless surface made of structured rubber, the Zeroseam belts were developed specifically to meet the needs of tube winding applications. The combination of a strong cord tension layer and their seamless design makes these belts highly flexible. It means that the belt pressure is applied evenly to the paper, allowing the belt to run at a lower tension, which significantly increases its longevity while also reducing high cost energy consumption. The rubber compound used is produced to Nitta’s own proprietary formulation and unites a high coefficient of friction with a strong resistance to abrasive materials such as paper. The result: reliable firm grip over a long service life.

“Frankly, we were surprised,” says Luc van Campenhout of Sonoco in Mechelen. “Of course we were expecting to see a marked improvement of the belt’s longevity, but the actual production numbers we achieved with these new belts go far beyond our expectations.” The service life of the Zeroseam belts exceeds that of the previously used polyamide belts by a factor of seven without loss of production speed or product quality. “Having tried many different suppliers’ solutions without seeing any significant changes, this was quite a pleasant surprise,” van Campenhout adds, pointing out the results with the Zeroseam ZS-TWL-42H belts on several of his machines.

The new line of Zeroseam belts is made in a moldless production process developed by Nitta technology, which allows rubber-coated seamless belts to be produced to customer-specified lengths and widths. Nitta Zeroseam belts are currently available in three different configurations, all of them customizable to customer needs, with additional belt types currently being developed for both tube winding machines and other applications.

In addition to industrial belting products, Nitta manufactures conveyor systems, plastic hoses and tubing, engineered rubber products, air filtration systems, industrial wipers and mechatronic sensor systems. These products are used in many industry sectors including logistics, paper processing and printing, banking automation, and textiles. In Germany, Nitta is headquartered in Düsseldorf and has a fabrication center near Frankfurt, where belts, tubes, and hoses are stocked and fabricated to customer specifications.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.