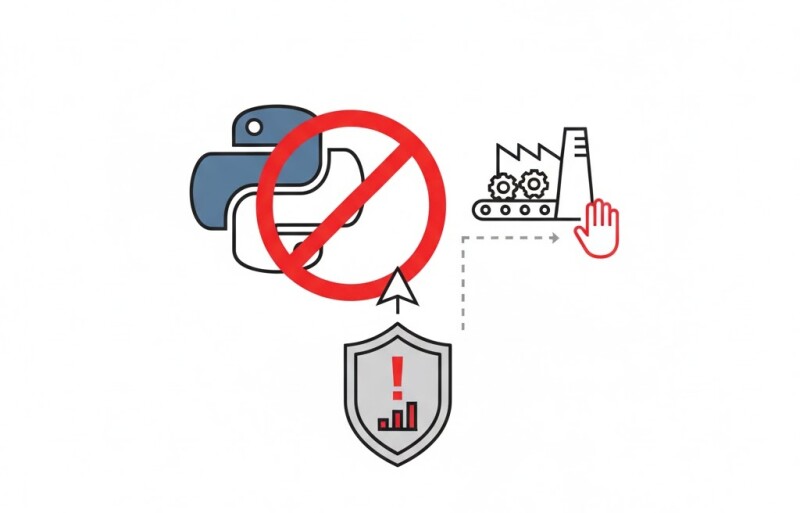

When to Keep Python Off the Line: Risk-Based Rules

Python is flexible, powerful, and easy to deploy — but that same flexibility makes it risky for real-time control. Knowing when not to use Python on the shop floor is part of professional engineering judgment.

When Python Doesn’t Belong

- Safety loops: Never place Python in SIL-rated control paths.

- Hard-real-time operations: PLC scan cycles and motion profiles require deterministic timing that Python cannot guarantee.

- High availability systems: Unhandled exceptions or library updates can break critical logic.

Safe Use-Cases

- Data analysis and reporting outside control loops.

- Predictive maintenance models running on isolated edge servers.

- Offline simulation and recipe optimization tasks.

Risk-Based Framework

Apply the same methodology used in safety systems — severity × likelihood × detectability — to assess each Python deployment. Where the score exceeds tolerance, isolate it via container or network segmentation.

Example Scenario

A metal forming plant ran a Python script to compute OEE directly on the HMI PC. After a Windows update caused the script to hang, the HMI froze mid-batch. The fix: moving the analytics task to a separate industrial edge node with MQTT output only.

Related Articles

- Python Next to PLCs: Safety, Sandboxing, and IPC

- Scheduling Data Jobs in OT: Cron, MQTT, and Triggers

- Testing Python Pipelines in a Simulated Plant

Conclusion

Python belongs in manufacturing — just not everywhere. Treat every script like a potential hazard, and apply isolation, supervision, and testing before it touches production data or control loops.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.