HAF Equipment (United States) - Press Release: A HaF Case Study by Michael Thiel (HaF Equipment).

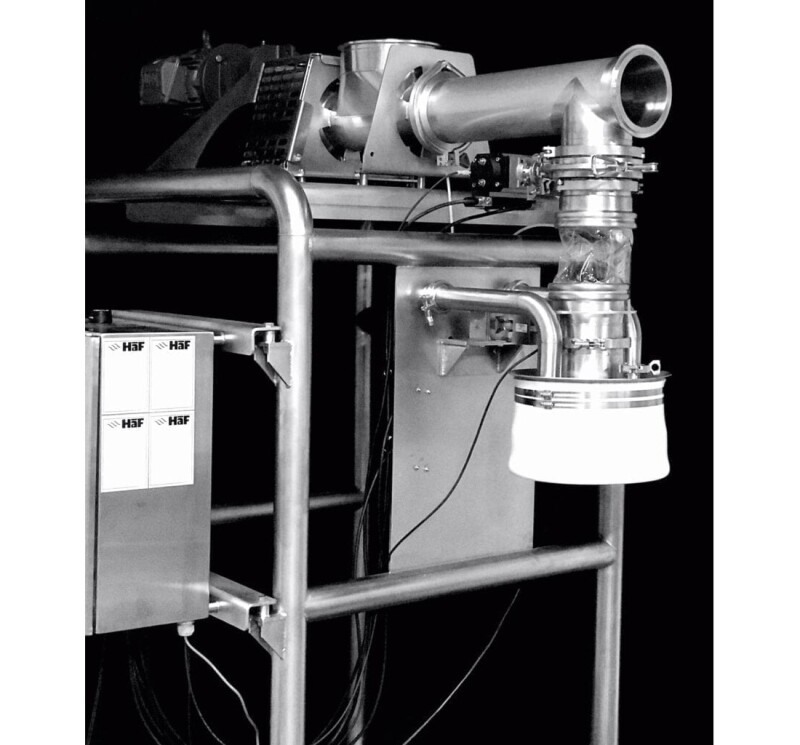

HaF Equipment recently commissioned a successful 50-Lb Bagger for a USDA application packaging spray dried powders from a milk based raw feed. This bagger project for our customer was not the first, as our customer appreciated the design of the HaF Bagger.

There are several important features that we included for this specific bagger:

1. Surge Hopper:

A simple item, such as a hopper, can be overlooked when designing a 50-Lb bagging system. The purpose of a surge hopper above the bagger is to provide residence time for the powder to settle. This settling period provides a more consistent flow of material at the bagger, thus providing more consistent weigh-ups. If you would like to know HaF’s design setpoint for residence time, email us and we will work with you on your application.

2. Variable Pitch Screw Auger:

For bagging applications, the screw auger design is critical. HaF has several different auger designs, depending on bulk density and flowability (sluggish or free flowing) of the material.

For dairy applications involving bagging (bag filling) spray dried powders, HaF has a specific designed auger setup tailored to both accuracy, poor flowing materials, and flood filling materials. We provide different auger profiles specifically suited to customers’ powder.

3. Inflatable Filler Head:

The operator places an open top bag on the filler head and uses a foot pedal to start the cycle. The inflatable filler head expands to seal the bag inlet. The bag is held in place on the filler head, which is connected to the load cell. The weigh up begins.

4. Shutoff Valve and Accuracy:

At the discharge of the screw auger we utilize a shutoff quick clean valve that will stop the flow of powder in order to meet the tolerances of the weigh up.

By utilizing the specifics of HaF’s designs, and the multipoint features of the feeder, HaF typically meets the weigh up accuracy of +/- 1%, easily. We have special designs that can achieve 0.1% accuracy. Contact us if you require this level of accuracy and we will share with you how we can achieve it.

5. Cleanability:

For our recent customer’s feeder, and all our sanitary designed feeders, we utiklize our design concept of “Tool Free Quick Take Apart”. HaF specializes in quick clean and easy to clean equipment. It is very important in sanitary applications that the operator can easily disassemble and clean the equipment, and then reassemble, in as shortest amount of time as possible. We get it. And we have answered.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.