Tamtron Group (Finland) - The logistics company Urbaser Oy uses in its trucks onboard crane scales by Tamtron. These scales, that are easy to fit and use, are nowadays necessary pieces of equipment as the invoicing of waste material is progressively changing from tracking the amount of lifts to weighing-based.

Tamtron’s onboard crane scales in use. Petteri Viitanen empties the recycling bank’s cardboard collection container into the truck. The scale hanging at the end of the boom measures the weight while lifting.

Urbaser has over 40 scales in various skip trucks and garbage trucks operating in different waste logistics operations around Finland – the majority of them in garbage trucks. The scales are connected to the vehicles’ loader cranes. Urbaser Group, headquartered in Spain and operating globally, has over 44 000 employees. The enterprise serves in the field of waste disposal taking care of collection and transport of waste material from households, recycling banks, and corporate and communal facilities.

Urbaser has in Finland over 120 trucks – by brand Volvos, Scanias and Merceder-Benzes. By color, the cars are always white. They are mainly garbage trucks, or garbage packers, familiar from urban traffic. Besides these, there are vehicles equipped with a demountable skip, with which waste from companies and other large waste containers are collected. One of these tasks is to maintain the logistics for emptying and transporting the Finnish Packaging Recycling RINKI Ltd’s “Rinki” recycling banks. At these collection points materials like cardboard, glass, metal and plastic are collected. Urbaser delivers the recovered materials forwards from these collection points. The metallic containers of the recycling bank are emptied to the skip truck’s container. For this process, it is necessary to lift the whole container up in the air. The trucks have loader cranes from the brands PM, Hiab or Palfinger. There are over 40 cars with loader cranes and they all have also the onboard crane scale. Waste disposal fees are increasingly developing to be weighing-based, and so the weight of the mass being handled needs to be known from the very start.

The scale module inserted between the loader crane’s boom end and the grapple’s rotator. The construction is solid and simple as is the installation. The scale is maintenance-free. Replaceable battery is located beneath the black lid.

Take control of kilos:

The scales Urbaser uses are Tamtron ANV onboard crane scales. According to Harri Hietala, manager at the Urbaser Oy, most of them are of the ANV DR10 make. The weighing capacities are 2 tonnes, 4 tonnes and special models up to 10 tonnes. The scale system that goes with the car consists of three parts: scale module, remote unit and a receiver.

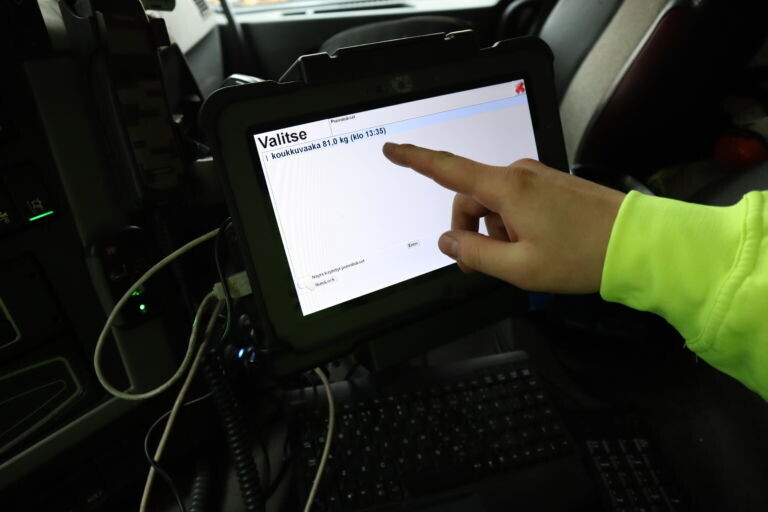

To determine a weight, first the handheld unit displays the weighing result on its display. Through the receiver connected to a cabin display the weighing information is stored immediately to the information systems and conveyed to the client. The channels are by Bluetooth.

“Once installed, scale functions well for a long time. Occasionally there are updates. Updates are done when needed with a USB port of the Windows-operated display.” Manager Harri Hietala, Urbaser Oy.

Driving with Petteri:

We set off with the driver Petteri Viitanen for a small round to inspect the scale’s operations in practise. At the “Rinki” recycling bank, in just few minutes the steel cardboard collection container is up in the crane end. By pressing the remote unit’s button, the device stores the weight in the crane. This transaction requires no more than a simple lift-up to measure the weight. Next the collecting container is emptied out to the car’s container equipped with a cardboard compactor. The empty container is then weighed to find out the net weight of the collected material. The information transmits from the remote unit to the car’s own display and from there with the records of the place and time to Urbaser’s information systems.

The car’s display collects all the information from the disposal point (i.e. place, weights and time) and communicates them to the client’s system via a data network. The information arrives even before the vehicle drives onwards from the collection site.

Using the scale does not slow down at all the emptying and the collected information is available immediately for further use. Petteri’s car also has the scale’s battery charger. The scale module uses batteries, as the scale unit hanging at the end of the loader crane would be difficult to operate with electricity. A replacement battery charges on the dashboard of the car as the other is installed in the scale. According to Petteri, the battery needs to be replaced few times in a week. This takes about a minute – open three hex keys, battery off and another in place. The remote unit notifies the charge status of the scale’s battery. The handheld unit in turn is charged with a USB charger. The scale itself is maintenance-free.

Take control of information:

One essential knowledge in today’s environmental logistics is the weight of the collected material. The invoicing is progressively changing from tracking the amount of lifts to weighing-based. This means that all the material is weighed. Besides invoicing, the weighed measurements are used for statistical purposes. In the future the drives can be optimized based on the collected material. Manager Harri Hietala is happy with the operations of Tamtron. A special thanks goes out to the maintenance department. If, for some rare reason, there is a problem with the scales there is always and quickly instructions to fix the problem. Besides this, the updates are informed by Tamtron very well.

“Our fleet of cars further expands before the year is over. They’ll have a few loaders, too, so it might be a case of me going to get some scales from the Tamtron factory”, concludes Hietalainen.

Text: Esa Suominen.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.