Cognex (United States) - With VisionPro® Deep Learning, Cognex offers a deep learning-based image analysis software specifically designed for factory automation.

For tasks in industrial image processing that can be solved by formulating rules, traditional machine vision systems are usually the right choice. However, these systems often reach their limits when the objects to be inspected introduce variability and cannot be easily autmated using rules-based programming. This problem occurs in the inspection of food, in the evaluation of soldered or welded seams, and in many other applications. For use cases like these, machine vision systems based on deep learning technologies have established themselves as an innovative solution in recent years.

Until now, the application of deep learning methods required extensive knowledge of the technology. VisionPro Deep Learning from Cognex significantly reduces this entry barrier through a graphical user interface that simplifies the training of the neural network for users.

Intuitive graphical training:

VisionPro Deep Learning tools are trained with images, unlike traditional image processing methods which are programmed with rules-based algorithms. VisionPro Deep Learning's intuitive graphical user interface provides a simple environment for controlling and developing applications and significantly reduces the effort required to collect images, train the neural network, and test it on different sets of images.

Users can choose from four image analysis tools in VisionPro Deep Learning. They are optimized for vision inspections in factory automation applications and therefore only require a small number of images for rapid training. Blue Locate, Red Analyze, Green Classify and Blue Read tools solve applications that are too complex for traditional rule-based image processing approaches.

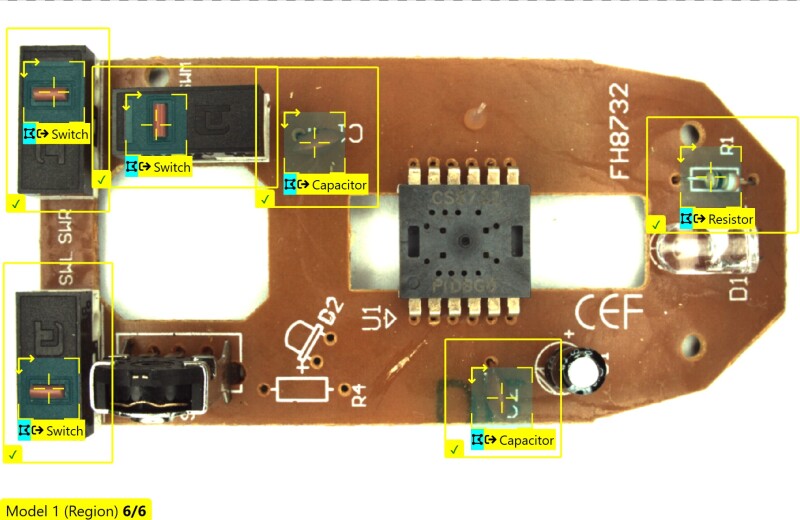

Identification with Blue Locate:

The Blue Locate tool is ideal for tasks where parts with different appearances need to be detected or counted. With its robust design, Blue Locate successfully identifies features on confusing backgrounds, low-contrast parts, and even parts that bend, change shape, or are poorly lit. Even with variations in perspective, orientation, brightness, gloss or color, Blue Locate reliably locates parts learned from sample images. For these reasons, Blue Locate is suitable for use in automated assembly verification, among other tasks.

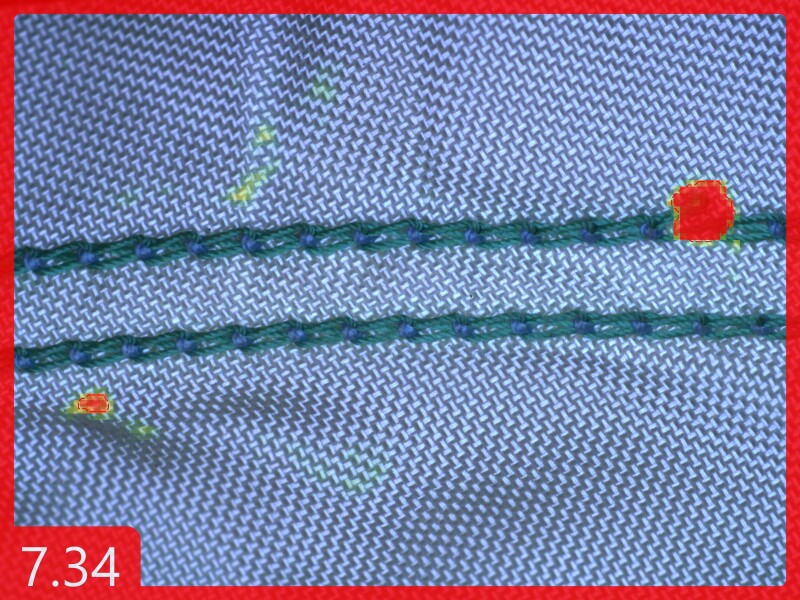

Detect defection with Red Analyze:

When the smallest defects must be found, despite different backgrounds and surface textures of parts, the Red Analyze defect detection and segmentation tool is the right choice. By training examples of good and bad parts, it is able to tolerate normal deviations in terms of appearance, while accurately detecting defects, impurities and other flaws.

Red Analyze can also be used to segment variable areas in an image. Examples include welds, glued or painted areas, and background features that are dynamically hidden from the image to facilitate other inspections.

Classification with Green Classify:

VisionPro's Deep Learning tool, Green Classify, is a robust classifier that can distinguish different classes of objects, identify defect types, and classify good and bad parts. Trained with a set of labeled images, Green Classify identifies objects based on their common features such as color, texture, material, packaging, and defect type, and divides them into classes. In doing so, the tool tolerates natural variations within the same class and effectively distinguishes acceptable variants from different classes. Green Classify handles even complex classification tasks very quickly and does not require complicated and time-consuming programming.

Optical Character Recognition with Blue Read:

Reading and recognizing fonts and codes is one of the most common tasks of image processing systems. Deformed, skewed or poorly etched characters can pose a real challenge, which can be easily mastered by using the Blue Read tool. The tool uses a pre-trained deep-learning font library and deciphers difficult characters on this basis.

The user-friendly GUI eliminates the need for complex programming and drastically reduces development time: users only need to define the target area, set the character size, and mark the characters in the images. In just a few steps, the robust tool can be trained to read application-specific plain text that cannot be decoded by conventional OCR tools. Plus, training can be completed without any image processing or deep learning knowledge. In addition, the optical debug function detects misread characters, which can then be easily corrected.

Deep learning and rules-based vision: the best of both worlds:

One major benefit of VisionPro Deep Learning is the unique ability to combine the available tools. This allows complex problems to be broken down into smaller individual steps to simplify project optimization and reduce the number of training images required. Another special feature of the new software environment is that developers can easily select the best tool for the given task by combining it with VisionPro's rule-based vision libraries. Projects can be created in the VisionPro Deep Learning development environment and then exported to a VisionPro project. In this way, VisionPro and VisionPro Deep Learning offer the possibility to combine the best of both worlds.

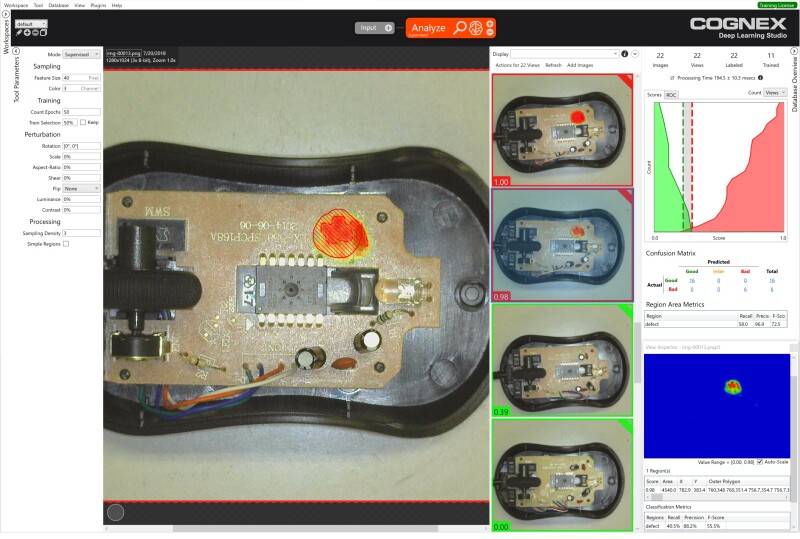

Picture 1 Caption:

VisionPro Deep Learning's intuitive graphical user interface allows for fast and easy development of applications.

Picture 2 Caption:

The Blue Locate tool is suitable for automated assembly or completeness checks, among other tasks, due to its ability to accurately identify different parts.

Picture 3 Caption:

Even with varying backgrounds or surface textures, the Red Analyze tool finds the smallest defects. In the example above, the tool detects seam problems in textiles.

Picture 4 Caption:

The Green Classify tool is a robust classifier that distinguishes different object types, identifies error types, and inspects and classifies images.

About Cognex Corporation:

Cognex Corporation designs, develops, manufactures, and markets a wide range of image-based products, all of which use artificial intelligence (AI) techniques that give them the human-like ability to make decisions on what they see. Cognex products include machine vision systems, machine vision sensors, and barcode readers that are used in factories and distribution centers around the world where they eliminate production and shipping errors.

Cognex is the world's leader in the machine vision industry, having shipped more than 2.3 million image-based products, representing over $7 billion in cumulative revenue, since the company's founding in 1981. Headquartered in Natick, Massachusetts, USA, Cognex has offices and distributors located throughout the Americas, Europe, and Asia.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.