Retrofit Guide: Upgrading Old Palletizers with Vision

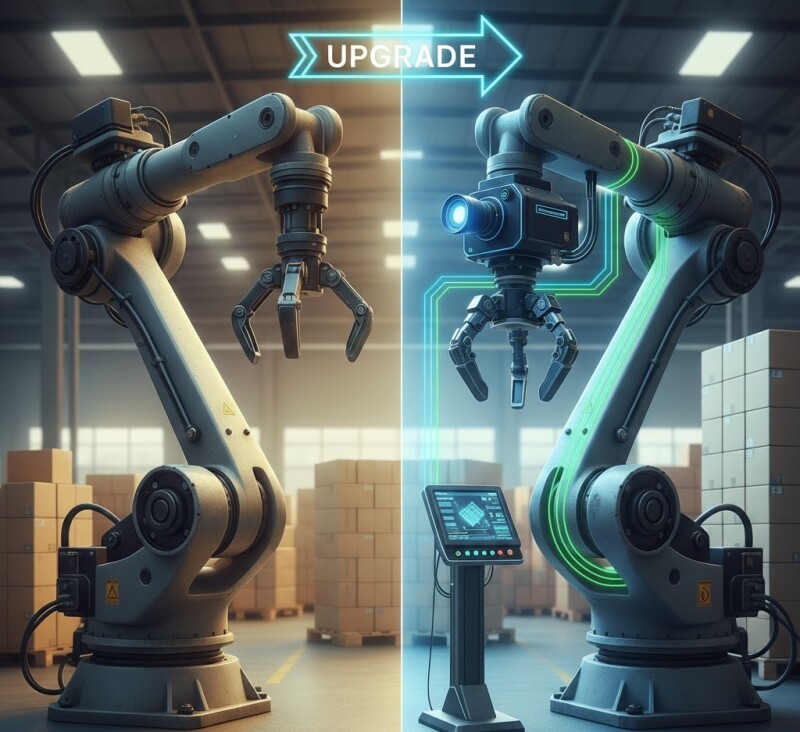

Not every facility needs a new palletizer. Many legacy systems can gain a second life with vision systems, new controls, and smarter grippers. Retrofitting adds flexibility without the cost or downtime of a full replacement.

Step 1: Assess the Existing Hardware

- Check robot mechanics — joint backlash, repeatability, and end-effector compatibility.

- Verify controller connectivity (Ethernet/IP, PROFINET, or Modbus TCP).

- Ensure sufficient I/O for camera triggers and safety inputs.

Step 2: Add Vision Intelligence

- Integrate 2D cameras for barcode or label alignment.

- Use 3D vision to handle mixed-case or irregular loads.

- Leverage AI-based object recognition to auto-generate pallet patterns.

Step 3: Update the Control Layer

- Upgrade to a modern PLC or IPC with EtherCAT or OPC UA support.

- Deploy a digital twin for simulation and validation.

- Connect data to MES or SCADA for OEE tracking.

Case Study

A logistics plant retrofitted a 2008 Fanuc M-410 palletizer with 3D vision and a new IPC. Throughput rose 25%, and scrap from misaligned boxes dropped by 80% — all without replacing the core robot.

Related Articles

- Cobot Palletizing in Tight Spaces: Stacked ROI

- Mixed-Case Palletizing: Vision and Path Planning

- Throughput vs Stability: How to Tune the Cell

Conclusion

Retrofitting with vision and modern control gives existing palletizers new intelligence. It’s a cost-effective step toward smart factories — without scrapping proven hardware.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.