Bürkert (Germany) - Bürkert is expanding its portfolio of mass flow meters (MFMs) and mass flow controllers (MFCs), Types 8742 and 8746, for gases to include variants with a standard signal and PROFIBUS-DP interface. The new generation enables simple device replacement or plant modernisation, while ensuring the usual high measuring accuracy and low-maintenance operation. Further, the robust housing allows unprotected field use, even in Ex Zone 2.

Measuring and controlling gases poses challenges for operators of plants with a long operational life. On the one hand, they want to use the latest measurement technology and, on the other hand, this technology must communicate via existing interfaces. The fluid specialists at Bürkert Fluid Control Systems therefore now offer their proven MFCs/MFMs, Types 8742 and 8746, as versions with an analogue or PROFIBUS-DP interface.

The thermal MEMS sensor is located directly in the gas flow and achieves very fast response times for highly dynamic measurements or gas control, for example in metal and glass production and processing, fermentation processes or filling and packaging machines. The MFMs/MFCs conform to FDA and USP Class VI and can be used in the pharmaceutical and food industries as well. A robust electronics housing with optional conformity to ATEX/IEC Ex Zone 2 Cat. 3G/D ensures safety in the field. As a result of the interface extension, even existing plants with established data acquisition can be easily upgraded to the latest generation of devices. High-level dynamics and measuring accuracy with very short response or setting times do not depend on the state of interface technology. Nevertheless, the latest MFCs/MFMs, Types 8742 and 8746, offer extended pressure and flow ranges as well as additional, application-specific software functions.

Flexible technology:

The MFCs/MFMs operate in the nominal flow rate range of 0.010 lN/min to 160 lN/min (Type 8742) or 20 lN/min to 2500 lN/min (Type 8746). Optionally, up to four real gas calibrations for various gases and mixtures can be stored in the device. Gas changeovers, for example for fermenters or molten metal treatment, are thus possible without any problems.

The entire range of new generation devices feature uniform M12 standard connectors for communication, ensuring easy installation and a reliable supply of spare parts. Thanks to the integrated configuration memory, devices can be exchanged quickly and easily via plug & play.

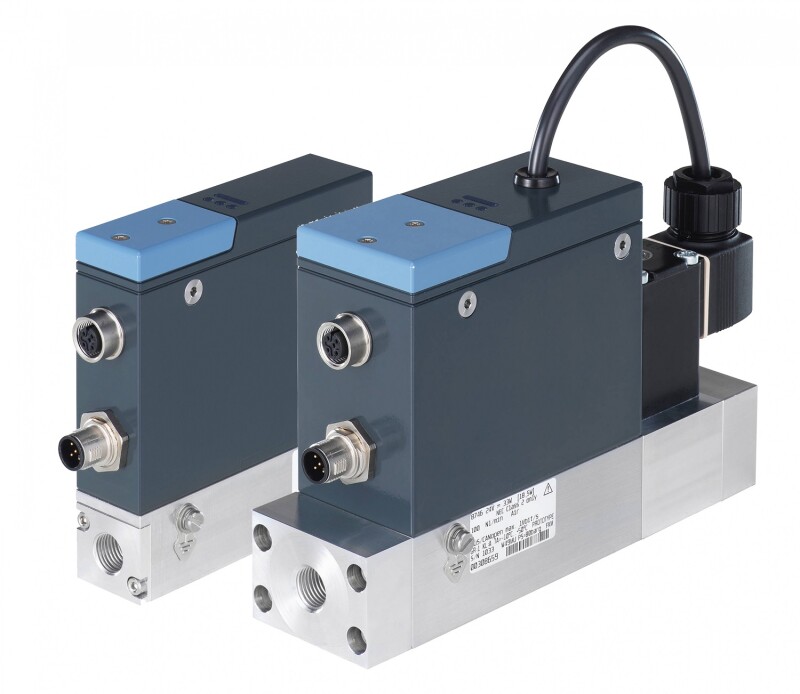

Picture Caption:

The MFCs/MFMs, Types 8742 and 8746, enable the efficient use of cutting-edge flow measurement technology despite older communication technology.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.