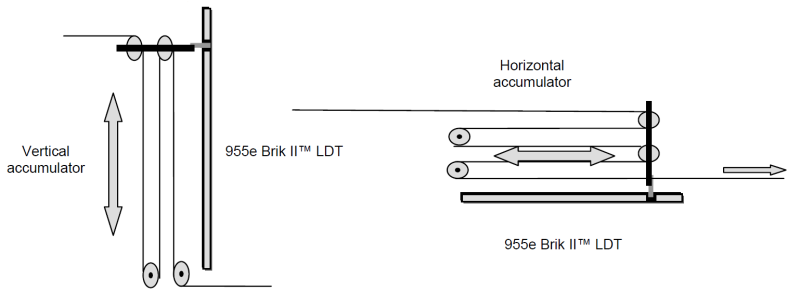

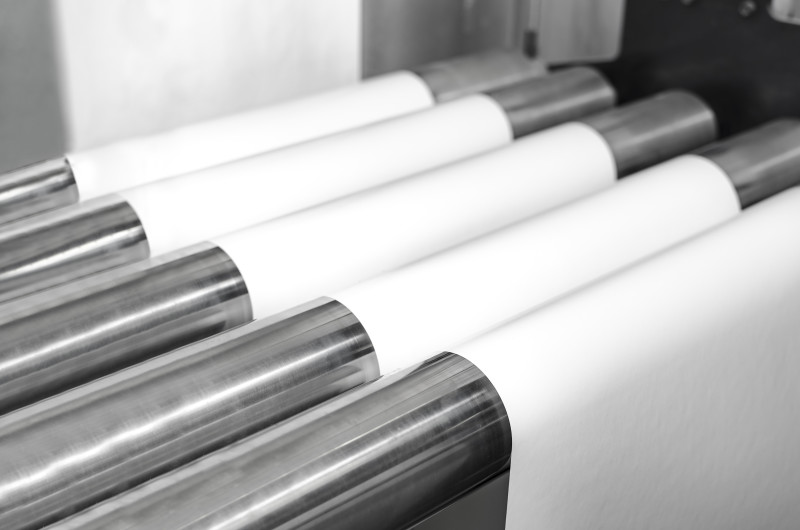

Ametek (United States) - In any continuous web printing processes, exact control of the print media contributes directly to optimized production speeds, achieved deadlines, reduced scrap and reduced downtime. An important part of the web process is the accumulator that stores enough material, so that when the roll (media) runs out, the machine does not need to be stopped. The accumulator roll position needs to be monitored to ensure the paper does not run out or tear. If the accumulator fail, the entire printing process will break down which can cost at least 2-3 hours of downtime and additional cost on the restart procedure. Often, accumulators are monitored by potentiometers. However, with the high amount of dither in these applications they are subjects to wear which can cause expensive crashes and downtime.

Perfect Accumulator Control Keeps the Process Running:

Keeping the web printing process unbroken through paper change, or smaller unforeseen issues, is crucial in coherence with deadlines, workflow and profitability. The accumulators are controlled best by Linear Displacement Transducers, also referred to as LDTs. This technology provides the precision and stable measurement that are needed. The magnetic sensor works almost without touching the position sensor and will not show wear as in contact type devices, such as linear potentiometers. Using linear displacement transducers is the most budget friendly solution in the long run, as these are designed to work flawlessly for years in the web industry.

Why Use LDT for Accumulators:

In some web processes the machine in question needs to accumulate material, such as paper, plastics, nonwovens or textiles, in order to keep the process rolling when it is necessary to change a roll, or when there is a bottleneck in the line.

The Options:

- String potentiometers, which are cables attached to a rotary potentiometer. These are not reliable and mounting the cable can be a nuisance. The cables are often very thin and can easily be broken.

- Linear potentiometers are resistive style probes that are prone to failure. They cannot tolerate dither and drift with temperature changes.

- The Gemco 955 eBrik II™ LDT which is easy to mount. The design provides a virtually wear-less magnetic sensor with magnetostrictive technology. Gemco 955 eBrik II LDT withstands constant exposure of humidity and high temperature whilst providing stable and exact measurement. These are some of the factors that make the Gemco 955 eBrik II linear displacement transducers the ideal solution for accumulator applications, not only when taking quality in consideration but also when comparing budget to lifetime.

Benefits:

The non-contact magnetostrictive technology used by the Gemco 955 eBrik II ensures longevity and reduced maintenance.

- Superior response and accuracy mean higher performance

- Cost effective compared to other technologies

- Competitive replacement of other Linear Displacement Transducers

- Programmable zero & span

- Rugged - Sealed to IP67 This secures a lower sensor cost over the lifetime of the machine, as well as fewer breakdowns of production, which is all leading to a safer budget.

About Gemco 955 eBrik II:

The Gemco 955 eBrik II linear displacement transducer (LDT) is an ideal alternative to the traditional low-cost linear potentiometer. The small and constant adjustments on a rotation press causes wear in switches and potentiometers. Magnetostrictive sensors offer non-contact position sensing and will therefore operate smoothly without experiencing wear and the following break-downs of production. The controlled humidity and temperature offers no challenge for the well-designed magnetic position sensors.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.