Ametek (Italy) - Lamborghini is an Italian manufacturer of luxury cars and V12 engines for power boat racing. In 2018 Lamborghini’s automobile product range consisted of three model lines, two of which are mid-engine two-seat sports cars while the third one is a front engined, all-wheel drive SUV.

Lamborghini uses the Chatillon CS2 force testing machine for testing the springs in their engine valves. The CS2 machine was supplied by Elis s.r.l., the Italian distributor of Chatillon force testing instruments.

Challenge:

Lamborghini performs compression tests on springs used in their engine valves. The compression tests are used to determine the force at a certain height, which is crucial data to obtain the correct design of the engine valve and the parts involved.

In the engines the valve springs are often double, meaning that a smaller spring is inside a larger spring, and the springs then work together. The compression tests are usually performed on a single spring, but in some cases it may be of interest to test the combination of the two springs as well.

For testing the springs, Lamborghini previously used a manual test instrument featuring a handwheel test stand with digital Miyutoyo scale along with a force gauge and Excel with values manually entered. They spent a lot of time on applying each test and on performing manual analysis of the test results.

The Lamborghini Technical Engineers desired a test solution that was more accurate, optimized for repeatability, that was fast in the processing of test results and that offered easy reporting. They estimated these functionalities as essential for their work. The Lamborghini R&D department therefore contacted Elis s.r.l., the Italian distributor of the well renoved Chatillon force testing instruments and Lloyd Instruments materials testing equipment.

Solution:

The data of interest for Lamborghini was the force at a given height.

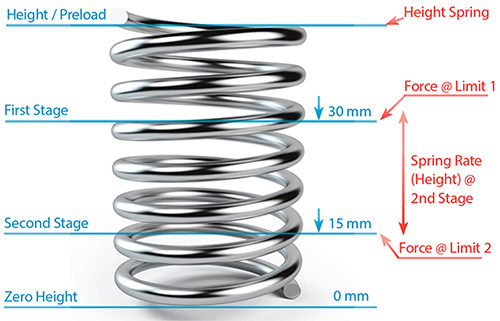

For this they needed to know three exact values:

- The Height at Preload. Free Height of the spring

- One compression stage at a known height

- One successive compression stage at a known height

At the end of the test the data needed was the data shown in red on the image to the right:

- HPL - Height at Preload. Free Height of the spring

- L - Load at Limit first stage. This is the force at the limit of first stage

- L - Load at Limit second stage. Is the force at the limit of second stage

- SR - Spring Rate. Result calculated in the second stage, calculation limits based on height (The spring rate could also be calculated in the execution of a single test step.)

Elis s.r.l. demoed the CS2 force testing machine from Chatillon as the CS2 offers all of the functionalities desired by Lamborghini at a lower cost than the price of an advanced materials testing machine. Accuracy, speed, repeatability and easy reporting was easy to obtain.

The CS2 force tester is ideal for testing applications up to 5 kN (1100 lbf) and its large color console offers intuitive test settings even down to personalization of test selection icons where it is possible to add own images for quick and easy recognition for the operator.

It offers its operator security and rapidity of use ensuring fast and consistent test results. Test results can be exported to Excel either manually or automatically.

The compression tests needed by Lamborghini was set by the operator using the Multi Stage mode.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.