Kistler Group (Switzerland) - Measuring vibrations at up to 1000 degrees Celsius.

It delivers reliable results at temperatures of 700 degrees Celsius over the long term and can even withstand temperatures of up to 1000 degrees for short periods of time. The 8211A sensor is certified to ATEX and IECEX for use in explosion protection. This makes it suitable not only for monitoring purposes, but also for use under extreme conditions in a wide variety of applications.

When measuring vibrations inside the combustion chambers of gas turbines, rocket or aircraft engines, ambient temperatures of the sensors are often in the high three-digit range. Under extreme conditions, these measurements must provide exact data as basis for further developments – for example on instabilities in the combustion process. However, only few sensors withstand the extreme heat and temperature fluctuations and still deliver reliable measurement data. The new 8211A sensor from Kistler is especially designed for such conditions in order to measure vibrations in various extreme industrial environments.

Maximum accuracy even at extreme temperatures:

The sensor owes its heat resistance primarily to the PiezoStar crystal at the heart of the accelerometer, which is especially suitable for these applications. Kistler grows the artificial crystal in its own laboratories. Quality fluctuations and supply bottlenecks, such as with the gemstone tourmaline, used in similar applications, are not a concern with the artificial crystal. In addition, the sensor's robust hardline cable is insulated with magnesium oxide and equally resistant to heat: Enduring temperatures of up to 1000 degrees Celsius is not a problem for sensor or cable.

Differential measurement chain ensures reliable results:

The functioning principle of the 8211A accelerometer from Kistler is based first and foremost on the piezoelectric effect: when force acts on the crystal, it generates an electric charge that is proportional to the acceleration. The accelerometer can measure this charge along an axis in both directions. Due to the sensor's basic insulated design the positive and negative charge is constantly evaluated. In combination with a differential charge amplifier a complete and stable differential measurement chain can be formed. This provides reliable data that is not influenced by environmental factors such as electromagnetic interferences.

Picture 1 Caption:

Measures vibrations under extreme conditions: the new 8211A sensor from Kistler.

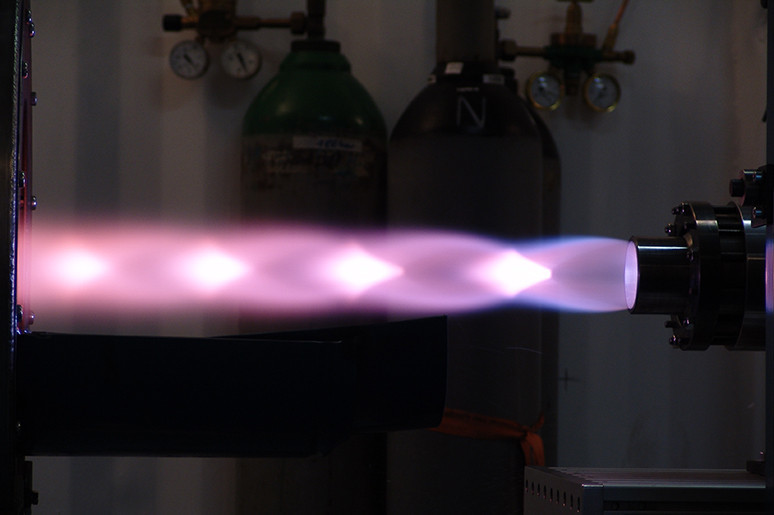

Picture 2 Caption:

The 8211A sensor is suitable for many applications with extremely high ambient temperatures, such as testing rocket engines.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.