Mitsubishi Electric Automation (China) - Located in the beautiful coastal city of Qingdao, Golden Packaging (Golden Pak) has many years of rich service experience in the ice cream industry, as well as providing all kinds of packaging equipment for many leading enterprises in the cold beverage industry such as Meiji, Wall's, Nestle, Yili, Mengniu, Bright Dairy, Hongbaolai, and Baxi. Golden Pak’s equipment is also exported to more than 60 countries and regions including the United States, Germany, Japan and Russia. With the support of Mitsubishi Electric and Qingdao Keling, they not only develop and upgrade special equipment for horizontal feeding, organizing, packaging, sorting and palletizing for many industries such as food and medicine industries, but also create a comprehensive solution for the packaging process by using the e-F@ctory framework.

In the years following 2000, the packaging industry in China developed very rapidly: on the one hand, packaging equipment could help customers reduce labor costs and improve the level of hygiene with the popularization of automation technology; on the other hand, a group of large enterprises emerged due to strong market demand. The traditional mode of small workshops could not adapt to large-scale production and standardized operation, and there was an urgent need for automation equipment with higher production efficiency. Golden Pak closely followed the development pace of their customers. With their stable product quality and timely responses, they had caught up with the “fast track” of the packaging industry and quickly opened up new opportunities in food and CPG industries. After that, with technical support from Mitsubishi Electric and Qingdao Keling, they focused on the development of non-standard, customized products to provide more value and services to meet the demand from their customers in the cold beverage and pharmaceutical industries.

In such a highly competitive market, Golden Pak has always maintained their excellent product quality, reasonable prices, stylish design and comprehensive services that already won them the trust and praise of their customers as they have steadily moved forward in both foreign and domestic markets! Nowadays, the export ratio of their products is higher than 50%, mainly to developed countries as far afield as Germany, the United States, the United Kingdom, France, Canada, Australia, Poland, the Czech Republic, Japan, and South Korea as well as sales throughout Asia, Africa and South America. To support this Golden Pak has opened a joint venture manufacturing plant in Indonesia to manufacture, sell and provide services locally, stepping towards a global production capability. Often the level of customers represents the strength of a company and this is especially true for Golden Pak: at present, they are working with top companies in the domestic and international food and pharmaceutical industries such as Unilever, Nestle, Wall's, Yili Group, Mengniu Group, Wandashan, but also not to miss mentioning New Hope, Charoen Pokphan, Hsu Fu Chi, Want Want, Baiyunshan, Nice, Sanjin Pharmaceutical Company Limited, and COFCO.

Jin Weijian, General Manager of Qingdao Golden Packaging Machinery Co.Ltd. said, “About 5% of Chinese private enterprises survive only for 10 years, and the average life span of small and medium-sized enterprises in the United States is less than 7 years, which indicates that it is not easy for private enterprises to do a good job. Golden Pak has been there for eighteen years. Many employees have been with the company through thick and thin. Yet the company has always been energetic, as we take 'creating value for customers' as our business tenet, which is consistent with Mitsubishi Electric's values.”

From packaging equipment and integration with the customer's production systems, to providing back-end packaging engineering and comprehensive services, Golden Pak helps customers increase production, reduce costs, ensure sanitary conditions, and realize value creation and enhancement. “We want to have a place in China's packaging machinery industry and make Golden Pak an influential brand in the industry.” Jin Weijian is confident about their corporate goals.

The improvement of technical capabilities is not limited to successfully completing the production task of a certain process, but also to optimize the structural design and improve the compatibility of the system. In the words of Jin Weijian, “Achieve optimal quality and price”.

After the new development ideas were determined, Golden Pak fully adopted Mitsubishi Electric products. This seemingly ‘expensive’ strategy was the most ‘beneficial’. In recent years, the competition in packaging industry has been particularly fierce. Packaging equipment components have become more and more expensive, but the prices of whole machines are declining.

“Mitsubishi Electric's products are stable in quality but with high prices, and end users want to buy inexpensive equipment. As a packaging equipment manufacturer, it is extremely hard to balance this contradiction, while obtaining reasonable profits, and ensuring the quality of the equipment. Fortunately, Mitsubishi Electric and Keling help us control costs through reasonable configuration and solve problems using their technology, so we have a strong base for competing,” Jin Weijian explained.

The technical support from Keling and Mitsubishi Electric was an important foundation for Golden Pak's transformation and a critical factor in helping users to upgrade their processes. "Golden Pak design the machines, while Mitsubishi Electric and Keling provide electrical and system design support. This collaboration enhances the co-operation between both the electrical and mechanical areas, with a future focus to add sorting equipment and box filling machines thus providing solutions for the entire back-end packaging." In this way, Golden Pak has transformed from a single equipment supplier to a packaging engineering provider.

The installation of an automatic Baumkuchen packaging line at a customer’s site illustrates the effectiveness of these joint solutions by Golden Pak, Mitsubishi Electric and Keling. The project lasted for two months with Keling's engineer Mr.Yang being stationed at the site, and Mitsubishi Electric's technicians and experts on-hand to provide support. Mr.Yang said, "Sharing success with customers is our philosophy. Mitsubishi Electric has been rolling out many reliable and convenient solution packages in recent years. They support manufacturers to adopt concepts that can create more value for customers."

This Baumkuchen packaging production line and the back-end project with multi-belt packaging adopted advanced technology and industry leading solutions. The production line has automatic sorting and feeding, automatic deoxidizer and labeling, automatic pillow packing, parallel spider robots, automatic boxing, various testing stations and other packaging elements. The integrated main controller watches over the entire process to maintain stability and to ensure things run smoothly.

Mitsubishi Electric not only has a full factory automation product line (from PLCs to industrial robots and processing machines, etc.), but it also has created the e-F@ctory digital manufacturing concept based on nearly a hundred years of manufacturing experience, built on a system framework and standards for creating intelligent factories.

"I hope that Mitsubishi Electric will strengthen its understanding of the industry and invest in science and technology, at the cutting edge of the packaging process, to support the needs of end users and promote the application and expansion of production lines, production workshops, and even the application of products and solutions for the whole plant." Jin Weijian has extremely high expectations for Mitsubishi Electric. He said that once all production lines start to use Mitsubishi Electric's technology, the stability of the packaging equipment will be better guaranteed.

Picture 1 Caption:

Golden Pak’s packaging equipment is exported to more than 60 countries and regions including the United States, Germany, Japan and Russia.

Picture 2 Caption:

With the support of Mitsubishi Electric and Qingdao Keling, Golden Pak developed and upgraded special equipment for horizontal feeding, organizing, packaging, sorting and palletizing for many industries such as food and medicine.

Picture 3 Caption:

There are a lot of products/brands that are familiar to Chinese people.

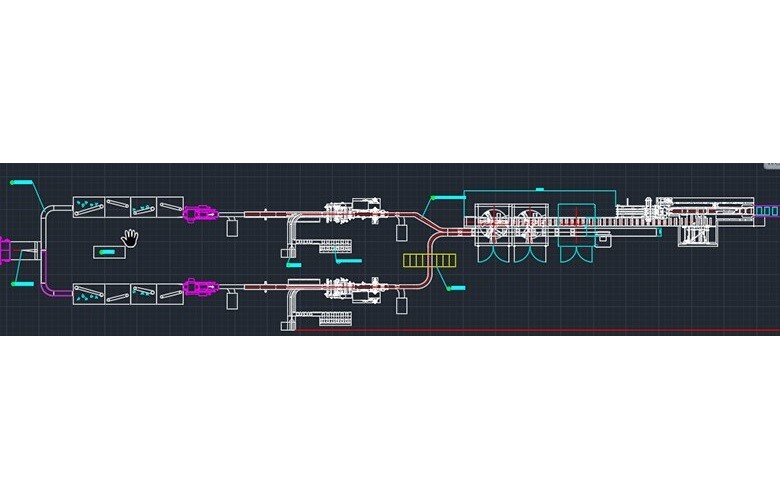

Picture 4 Caption:

Automatic Baumkuchen packaging production line project.

About Mitsubishi Electric Corporation:

With 100 years of experience in providing reliable, high-quality products, Mitsubishi Electric Corporation (TOKYO: 6503) is a recognized world leader in the manufacture, marketing and sales of electrical and electronic equipment used in information processing and communications, space development and satellite communications, consumer electronics, industrial technology, energy, transportation and building equipment. Mitsubishi Electric enriches society with technology in the spirit of its “Changes for the Better.” The company recorded a revenue of 4.194,4 billion yen (U.S.$ 37,8 billion*) in the fiscal year ended March 31, 2021.

*U.S. dollar amounts are translated from yen at the rate of ¥111=U.S.$1, the approximate rate on the Tokyo Foreign Exchange Market on March 31, 2021

About Mitsubishi Electric Factory Automation Business Group:

Offering a vast range of automation and processing technologies, including controllers, drive products, power distribution and control products, electrical discharge machines, laser processing machines, computerized numerical controllers, and industrial robots, Mitsubishi Electric helps bring higher productivity – and quality – to the factory floor. In addition, our extensive service networks around the globe provide direct communication and comprehensive support to customers.

About Factory Automation EMEA:

Mitsubishi Electric Europe B.V., Factory Automation EMEA has its European headquarters in Ratingen near Dusseldorf, Germany. It is a part of Mitsubishi Electric Europe B.V. that has been represented in Germany since 1978, a wholly owned subsidiary of Mitsubishi Electric Corporation, Japan.

The role of Factory Automation EMEA is to manage sales, service and support across its network of local branches and distributors throughout the EMEA region.

About e-F@ctory:

e-F@ctory is Mitsubishi Electric’s integrated concept to build reliable and flexible manufacturing systems that enable users to achieve many of their high speed, information driven manufacturing aspirations. Through its partner solution activity, the e-F@ctory Alliance, and its work with open network associations such as The CC-Link Partners Association (CLPA), users can build comprehensive solutions based on a wide ranging “best in class” principle.

In summary, e-F@ctory and the e-F@ctory Alliance enable customers to achieve integrated manufacturing but still retain the ability to choose the most optimal suppliers and solutions.

*e-F@ctory, iQ Platform are trademarks of Mitsubishi Electric Corporation in Japan and other countries.

*Other names and brands may be claimed as the property of others.

*All other trademarks are acknowledged.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.