Morehouse Instrument Company, Inc. (United States) - What is the best load cell I can use as a reference standard? This question appears straightforward, but once we start to examine the issue, it takes a series of questions to answer. The most common answer is, "Well… that depends on what your expectations are."

If your expectation is only performance, without regard to price and ergonomics, the answer is vastly different than if the best value is a consideration. Therefore, to fully answer this question we will address some basics regarding the selection of a load cell as a reference standard. The factors to consider are price, actual performance characteristics, specifications, ergonomic issues, and value.

Once you have chosen the best load cell, if you have a calibration with significant uncertainties, a substandard meter, or the wrong adapters, the load cell performance will be inferior. Thus, we will consider the uncertainty of the laboratory performing the calibration and some meter and adapter options to support the reference standard load cell.

Reference Standard Setup:

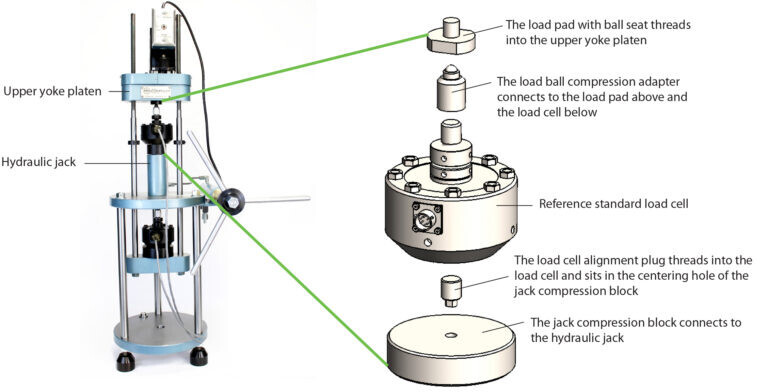

To start let’s look at an example of a reference standard load cell in a Morehouse Universal Calibrating Machine.

The reference load cell is mounted in compression and the breakout picture shows the adapters that are used to mount the reference standard. These adapters facilitate keeping the line of force pure by centering the load cell in the machine. The adapters are machined, sometimes heat-treated, and use connections such as ball adapters, and sphericals. These ball adapters considerably improve the performance characteristics of the load cells. Initial testing with and without the load ball compression adapter increased reproducibility by 30 – 40 %.

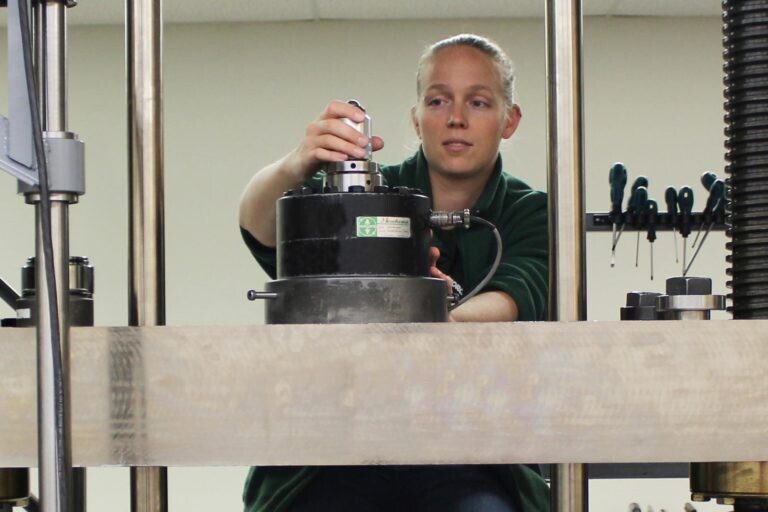

At Morehouse, we calibrate the load cell using the ball adapter shown. Figure 2 shows a load cell with a load ball compression adapter being set up for calibration. The expectation from anyone making force measurements should be to replicate use. Not doing so can produce significant errors. Several articles and papers show dramatic differences in load cell output and performance by using different adapters. Depending on the device, these errors can range from 0.01 % to 5 %. More information on adapters and calibration errors can be found here.

Calibration with Low Uncertainties:

When you think of a great reference standard load cell, you must consider the uncertainty of the laboratory performing the calibration. This is important because the uncertainty of your new reference standard load cell cannot be less than that of the laboratory performing the calibration.

For comparison, consider a calibration at Morehouse and at NIST. At Morehouse, most of our calibrations are performed using deadweight machines known to be within 0.002 % (k = 2) of applied force. If we use transfer machines, the uncertainty goes up to 0.01 % of applied force or higher. NIST has the lowest uncertainties because they have deadweight calibrations up to 1,000,000 lbf with uncertainties as low as 0.0008 % (k = 2). On average, the price is four times higher than Morehouse at 0.002 % (k = 2).

Is there a vast difference between these numbers? Not really when you look at the overall uncertainty of the reference standard load cell and factor in resolution, repeatability, stability, and environmental influences. If you are going for the absolute lowest value possible, go with NIST or buy a deadweight machine from Morehouse.

Let us compare 0.002 % to 0.01 % or 0.05 % using transfer standards (non-deadweight) such as a load cell in a dynamic calibrating machine. Most likely, there will be a significant difference because you have changed the starting uncertainty of the measurement by a factor of 10 – 25 times that of starting with deadweight. No matter what load cell system you purchase, it will be limited by those much more significant uncertainties.

Therefore, the suggested starting point is to insist on a deadweight calibration. Consider NIST if the price is not an issue.

Price Considerations:

If the price doesn't matter much, then a deadweight machine might be in your future. Price is always an important consideration. If someone says they want the best reference standard load cell, then they may hear, "Can you wait a year to have a specialty load cell made?" That is what we did for our 4.4 MN (1,000,000 lbf) load cell.

The price of the load cell and meter over a decade ago eclipsed $150,000. Each year, NIST performs a calibration for approximately $30,000, and we get a report back with an ASTM Lower Limit Factor between 11 – 16 lbf. This allows us to use one reference standard to calibrate other load cells from approximately 32,000 lbf to 1,000,000 lbf without changing standards. We pair this custom load cell with a $50,000 HBM DMP40 meter, which is nearing obsolescence and will soon be replaced by the HBM DMP-41.

Compare the $160,000 plus load cell with a Morehouse load cell and 4215 indicator. In the report below, the ASTM Lower Limit Factor is double that of the GTM/Morehouse Custom with HBM indicator, and the price is roughly 1/10 of the highest performing load cell we know about, plus the $30,000, plus calibration.

The initial equipment price is 1/10 of the other system, and the performance is excellent, although it is not as good as the system costing ten times more. Most labs would love the numbers that the Morehouse system with 4215 indicator is capable of. For comparison, the approximate price of a 1,000,000 lbf deadweight machine is $10,000,000, and a 1,000 lbf deadweight machine is around 1/100 of that cost. However, we are not showing the full details yet. Looking at the performance characteristics sheds more light on how good the system is.

Actual Performance Characteristics:

When we look at load cells, we need to consider how reproducible the results are and how stable the system is between calibration intervals. We should also look at creep characteristics, zero return, how well the load cell is temperature compensated, and non-repeatability.

Many people get caught up in the wrong things. They look at non-linearity, SEB, and other specifications. These may not matter if the calibration is performed following a standard such as ISO 376 or ASTM E74; then these specifications are likely irrelevant. These standards use higher-order curve fitting routines and rely on the use of polynomial equations. We have several articles on calibration equations, ASTM E74, ISO 376, and why accuracy statements do not belong on some calibration certificates, which can be found in our blog.

Some may fail to consider how good the load cell is between calibrations. You can have great calibration numbers, but then find the load cell and meter have more significant drift than expected. This can increase the overall uncertainty by two to ten times the initial calibration numbers.

What you really want to know is the expected performance of the load cell. Both ASTM E74 and ISO 376 are standards that do an excellent job of giving us the right expectation. The better these load cells perform when following these standards, the better we can expect the load cells to perform.

Morehouse lists how we guarantee our load cells to perform to these standards because these are the performance characteristics that tell you how good the load cell is. They are not made up of numbers. They are a guarantee of how reproducible the measurement should be when used in a similar environment.

There are some simple things that are often overlooked. For example, there are some very high-end load cells on the market. The performance looks fantastic until you calibrate them. Are the load cells bad? No! They are not bad; they are difficult to calibrate.

Numerous manufacturers make fantastic load cells that do not calibrate well. This is because they are less rigid, making them super sensitive to any fluctuation. When you start with the best calibration (deadweight), the weights tend to swing, the machines are never perfectly level, and everything deflects. These load cells pick up all of that in the measurement, and they do not calibrate well because of it.

Some high-level industries that own their deadweight frames have purchased these super sensitive load cells and found that they cannot get repeatable numbers because they are too sensitive.

At Morehouse, we do not typically recommend one of these load cells. Our Ultra-Precision load cell is rigid enough to calibrate very well. If we made a better load cell, it would be more sensitive and pick up all the calibration noise, for lack of a better term. That brings us to overall value.

Value:

What is the best value? Is it the super-duper load cell that picks up all the calibration noise? Is it a precision class load cell? A thorough needs assessment of nice to have's versus actual needs will lead you to the right choice.

If the goal is the largest loading range with the smallest uncertainty, then our Ultra-Precision load cell is an excellent choice. However, a 500 kN (112,000 lbf) load cell weighs around 26 kgs (57 lbs). HBM makes some fantastic load cells as well, which also are heavy and tend to have a higher price tag.

In some instances, the HBM load cell may be the better load cell. One case would be if the requirements are for a combined loading range using both incremental (ascending) and decremental (descending) loading.

The figure above shows an example of a shear web load cell. Typically this is the best design for many compression and tension applications. Other manufacturers make this style of load cell, and many are great as long as they have a tapered base and integral adapter.

Value-wise the best value might be our Precision class load cells. They are almost half the price of the Ultra-Precision cell and the specifications, which do not tell the entire picture, are not half as good. In fact, what is guaranteed is an ASTM E74 Class A lower limit better than 4 %. The load cells often calibrate much better than that.

Pairing your load cell with the right meter is essential to maintaining performance. Suppose you have a Morehouse Ultra-Precision load cell, or HBM TOPT-Transfer load cell, and pair it with a commercial off the shelf lower performance meter. You will not get the full benefit of the load cell because the meter will severely limit the performance characteristics.

We do get asked, "What is the best meter I can use with my load cell?" The answer is an HBM DMP-41 and the price tag is about $60,000. For many, this is way too expensive. A more economical solution is the Morehouse 4215, which is about $3,000. The calibration report from NIST (Figure 4) shows a Morehouse 1,000,000 lbf load cell using a 4215 indicator. The 4215 indicator has about 400,000 counts compared to 2,500,000 on the HBM DMP 41.

However, buying the best load cell and meter usually requires some method to physically lift and mount the load cell into a machine. If the calibration laboratory does not have the proper lifting mechanisms, a 26 kg (57lb) lift, or heavier on shear web load cells over 50 kN, may not make sense.

Ergonomic Issues:

If weight is an issue, you can get other style load cells with similar performance characteristics. However, there is usually a trade-off on the expected performance. For example, consider our lightweight compression-only multi-column load cell. The load cell is not suitable for tension applications, and the performance is similar to a precision load cell with an ASTM Class A loading range of better than 4 % of capacity. The Ultra-Precision is twice as good, but weighs about five times more than this load cell.

The bottom line is that there will always be a trade-off between ultimate performance and what is generally accepted to meet all the criteria.

At Morehouse, we educate our customers and provide tools to help them make a decision that makes the most sense.

I take great pride in our knowledgeable team at Morehouse, who will work with you to find the best load cell to use as a reference standard for your application. If we do not make that load cell, chances are we can source it, put together a complete system including transportation cases, and provide the best level of calibration next to NIST.

We have been in business for over a century and focus on being the most recognized name in the force business. That vision comes from educating our customers on what matters most, having the proper discussions relating to force calibration concepts, so everyone uses the proper methods and math.

Everything we do, we believe in changing how people think about force and torque calibration. We challenge the "just calibrate it" mentality by educating our customers on what matters, what causes significant errors, and focus on reducing them. In addition, Morehouse makes simple-to-use calibration products. We build fantastic force equipment that is plumb, level, square, rigid and provide unparalleled calibration service with less than two-week lead times.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.