Ability Fabricators Inc. (Canada) - When making personal care products, there are approximately over 2,500 unique ingredients to choose from. In fact, a typical product has 15 to 50 listed on its label. In just this industry alone, the vast range of ingredients mean they must be handled, mixed and processed using reliable equipment.

In addition, manufacturers also need to maintain consistent quality across all production lines. This challenge for consistency appears across all industries as wide-ranging as cosmetics, agricultural chemicals, and baked goods. One such way to achieve reliable dry or powdered products is through industrial ribbon blenders. These blenders mix dry solids or powder components to create the items that ultimately land on a consumer’s table, medicine cabinet, or under their sink.

In this post, Ability Fabricators will be exploring the many industrial uses of stainless steel ribbon blenders and how they can help manufacturers create exceptional quality products for their consumers.

What are Ribbon Blenders?

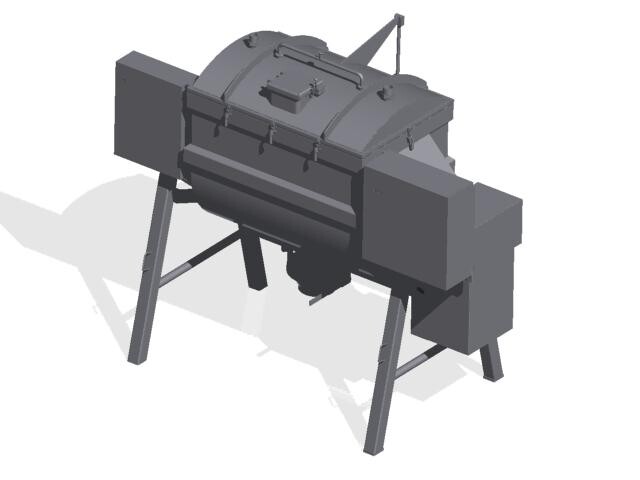

Ribbon blenders have U-shaped troughs and special ribbon agitators that move materials through the trough in two different directions. This mixes the batch quickly and thoroughly to cut down on production time. They can mix powders together, powders with liquid, and thicker materials such as paste and putty.

Uses for Ribbon Blenders:

At Ability Fabricators, our stainless steel blenders make blends that are used in chemical production, spice combos for food, medical compounding, and more.

With a ribbon blender in your facility, you can manufacture a wide range of products, including for:

Food:

In the food and beverage industry, there is a need to create mixes that can be used in final recipes, like bake mixes and sugar blends. Some of these premixes you might buy to make food at home or they might be used in large-scale food production. Stainless steel mixers meet food safety needs and do not impact the taste of your product.

Ribbon blenders help get mixtures evenly mixed or bring in small amounts of liquid for coating other parts. They work well with food items that involve mixing items of different sizes as well, like making trail mix.

Some examples of how they are used include:

Instant soups and sauces – complex recipes that can have powdered bits and other sized items like spices, stabilizers, and dehydrated vegetables that need to be gently mixed for even distribution

Baking mixes – solids like fats, oils, flavours mixed into powders without clumping

Herb and spice blends – even mixing of fragile bits and sometimes add in liquids like fats or extracts

Instant beverages – powered made into uniform granules to improve how they work

Baby formula – premix fine additives like vitamins and micronutrients, then mix in with bulk materials

Plant-based – even mixing of spices, binding agents and texturizers to get the right taste, texture, and appearance

Cereal – evenly add liquid flavouring or colouring to flakes

Coffee beans – spraying flavouring oil after roasting

Cake batter – mixing liquids into dry ingredients

Protein powder – combining various dry and solid elements into a fine powder

Premixes – mixes of grains and flavours for energy bars, fortified cereals, and oatmeals

Personal Care and Cosmetics:

Some difficult challenges exist in processing personal care products and cosmetics. They run from creating stable emulsions to the seamless blending of colours and fragrances.

Ribbon blenders serve a vital role here as they can deal with mixing a wide range of ingredients to create formulas that are safe and consistent.

Common applications for ribbon blenders in the cosmetics industry include:

- Make-up – blush, eye shadows, and others with solids, powders, colours, and scent mixed together

- Baby and body powders

- Pigment premixes – for makeup uses like lipstick and mascaras

- Premixes for skincare like face lotions and anti-aging creams

- Toothpaste – intermediate stages and the final product

- Wax emulsions – for use in hair care and styling products as well as make-up pencils

- Sunscreen – thorough mixing of active ingredients to ensure efficacy

- Body washes and shower gels

Chemical:

The chemical industry covers everything from household cleaners to pesticides and paints. Chemical manufacturers need a machine that can do gentle mixing for some products and intense mixing for others in the same device.

These products have the same needs for consistent and homogeneous mixtures as in other industries. The active ingredients have to be properly blended with fillers, lubricants, and other additives to ensure the product works as it should.

- Household cleaners

- Detergent powder – need to blend powders with additives along with liquids like perfumes and colourings

- Paints and varnishes

- Drywall compound

- Pesticides and fertilizers – often need liquid components like oil or active ingredients mixed into powders or other granules

- Automotive – fine powders for powder coatings

- Battery compounds – accurate batching of pastes and slurries used in various battery types

- Fuel cell powders – can thoroughly blend a lithium mixture without producing a lot of heat

Pharmaceutical and Nutrition:

Proper mixing of ingredients is mission-critical in the drug industry to make sure consumers get the correct dosage. Ribbon blenders help ensure batch quality that delivers precise amounts of active ingredients with gentle mixing and will also prevent any ingredient damage in production.

The mixers are often used to add binders to powder ingredients to create tablets or liquid flavouring to supplements. For nutrition products, colours and flavourings are also important as well as the proper blending of the various elements.

- Creams and ointments – mixed to get emulsifiers combined with active ingredients

- Coating tablets

- Dental impression material

- Antacids – binder added in with powdered ingredients, including colours and flavours

- Multivitamins – colour and flavouring additives mixed with active ingredients

Need More Information On Industrial Ribbon Blenders?

Whether mixing cosmetics or cake batter, industrial ribbon blenders prove to be a versatile choice for combining powders, liquids, and pastes. Their design results in efficient blending with little to no damage to the material during mixing. Manufacturers utilizing ribbon blenders get a consistent mixture every time, allowing them to deliver reliable quality to their customers.

Interested? Submit your enquiry using the form below:

Only available for registered users. Sign In to your account or register here.