High-Mix Robotics: Soldering, Dispensing, and Micro-Assembly

- October 28, 2025

High-Mix Robotics: Soldering, Dispensing, and Micro-Assembly In electronics manufacturing, high-mix, low-volume production has always challenged...

Read MoreESD-Safe Automation: What Integrators Forget

- October 28, 2025

ESD-Safe Automation: What Integrators Forget Electrostatic discharge (ESD) can silently destroy microelectronic components. As robots take over h...

Read MoreHow to Avoid Creating a New Data Silo with Your UNS

- October 28, 2025

How to Avoid Creating a New Data Silo with Your UNS The irony of many Unified Namespace (UNS) projects is that they end up creating another silo...

Read MoreBridging OT and IT: Governance for Shared Data

- October 28, 2025

Bridging OT and IT: Governance for Shared Data Operational Technology (OT) and Information Technology (IT) have historically worked in silos &mda...

Read MoreNaming Conventions for UNS: Keep It Human, Keep It Hierarchical

- October 28, 2025

Naming Conventions for UNS: Keep It Human, Keep It Hierarchical A Unified Namespace is only as usable as its naming scheme. Engineers, analysts,...

Read MoreData Ownership in OT: Who Owns What, and Why It Matters

- October 28, 2025

Data Ownership in OT: Who Owns What, and Why It Matters As plants adopt Unified Namespace architectures, data ownership becomes a governance chal...

Read MoreDesigning a Plant-Wide Data Model That Scales

- October 28, 2025

Designing a Plant-Wide Data Model That Scales A Unified Namespace (UNS) only delivers value if its underlying data model is consistent, scalable,...

Read MoreQuery Patterns for Fast Root-Cause Analysis

- October 28, 2025

Query Patterns for Fast Root-Cause Analysis When a production issue strikes, time is everything. Engineers need historian queries that return res...

Read MoreData Retention in Regulated Industries: How to Stay Compliant

- October 28, 2025

Data Retention in Regulated Industries: How to Stay Compliant Pharma, energy, and food manufacturers face strict requirements for how long produc...

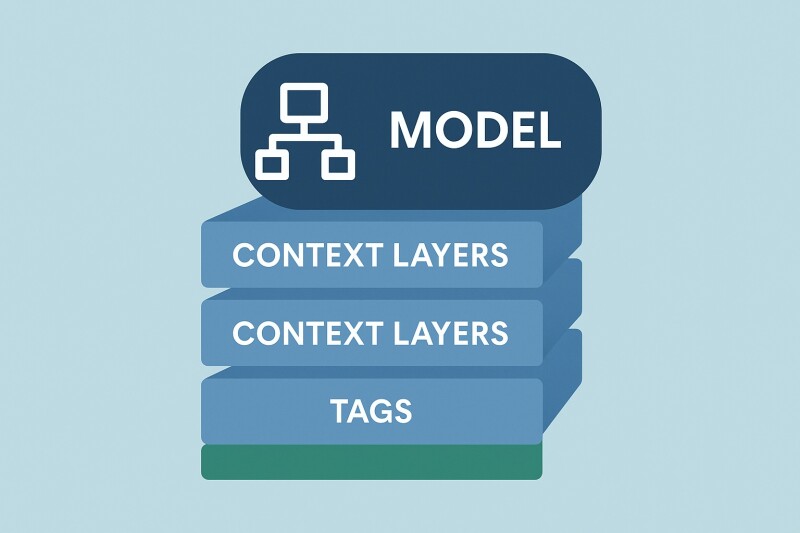

Read MoreFrom Tags to Models: Context Layers That Unlock Value

- October 28, 2025

From Tags to Models: Context Layers That Unlock Value Industrial data becomes exponentially more valuable when structured. Moving from raw tags t...

Read MoreChoosing a Time-Series DB for OT: Requirements That Matter

- October 28, 2025

Choosing a Time-Series DB for OT: Requirements That Matter Not all time-series databases are created equal. In OT environments, performance and r...

Read MoreModernizing the Historian: Compression, Context, and Contextualization

- October 28, 2025

Modernizing the Historian: Compression, Context, and Contextualization The plant historian has evolved from a simple tag logger to a contextual d...

Read MoreTying OEE to Profit: A CFO-Friendly Guide

- October 28, 2025

Tying OEE to Profit: A CFO-Friendly Guide For many executives, OEE feels like a technical metric with unclear financial meaning. Translating equi...

Read MoreRun Rules: What to Alert On (and What to Ignore)

- October 28, 2025

Run Rules: What to Alert On (and What to Ignore) Not all alarms are created equal. A line that alerts too often trains operators to ignore signal...

Read MoreLoss Trees That Operators Actually Use

- October 28, 2025

Loss Trees That Operators Actually Use Loss trees are visual tools that categorize productivity losses into availability, performance, and qualit...

Read MoreOEE That Drives Action: From Trend to Root Cause

- October 28, 2025

OEE That Drives Action: From Trend to Root Cause Overall Equipment Effectiveness (OEE) is one of the most used metrics in manufacturing — b...

Read MoreChangeover Reduction with Data: SMED Meets Analytics

- October 28, 2025

Changeover Reduction with Data: SMED Meets Analytics Single-Minute Exchange of Dies (SMED) has long been the gold standard for reducing changeove...

Read MoreIntegrating MES with ERP and LIMS: Patterns That Don’t Break

- October 28, 2025

Integrating MES with ERP and LIMS: Patterns That Don’t Break MES integration with ERP and LIMS often fails due to poor data mapping or uncl...

Read MoreKPIs to Hold Your MES Vendor Accountable

- October 28, 2025

KPIs to Hold Your MES Vendor Accountable Choosing a MES vendor is only the beginning — ensuring performance over time requires measurable e...

Read MoreRecipe, Genealogy, and eDHR: What a Modern MES Must Do

- October 28, 2025

Recipe, Genealogy, and eDHR: What a Modern MES Must Do Modern Manufacturing Execution Systems (MES) have moved far beyond scheduling and reportin...

Read More